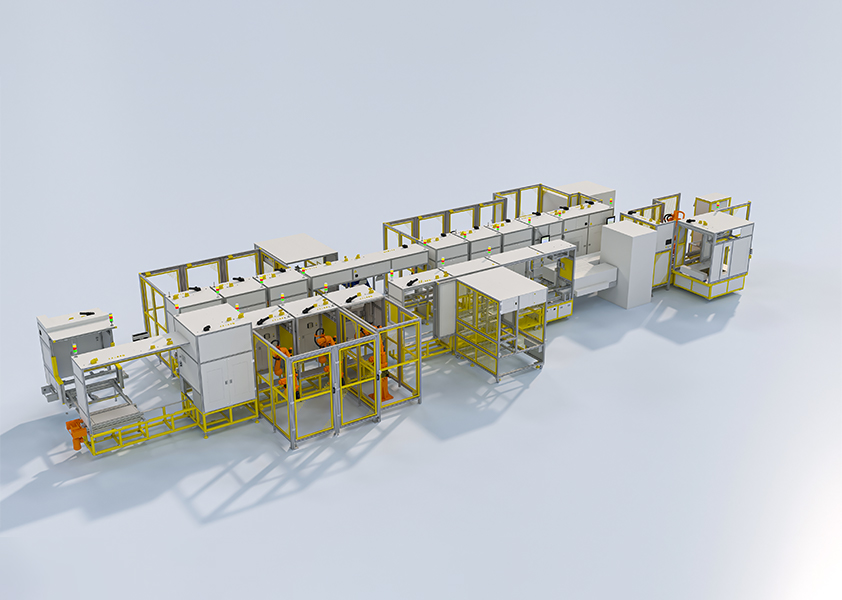

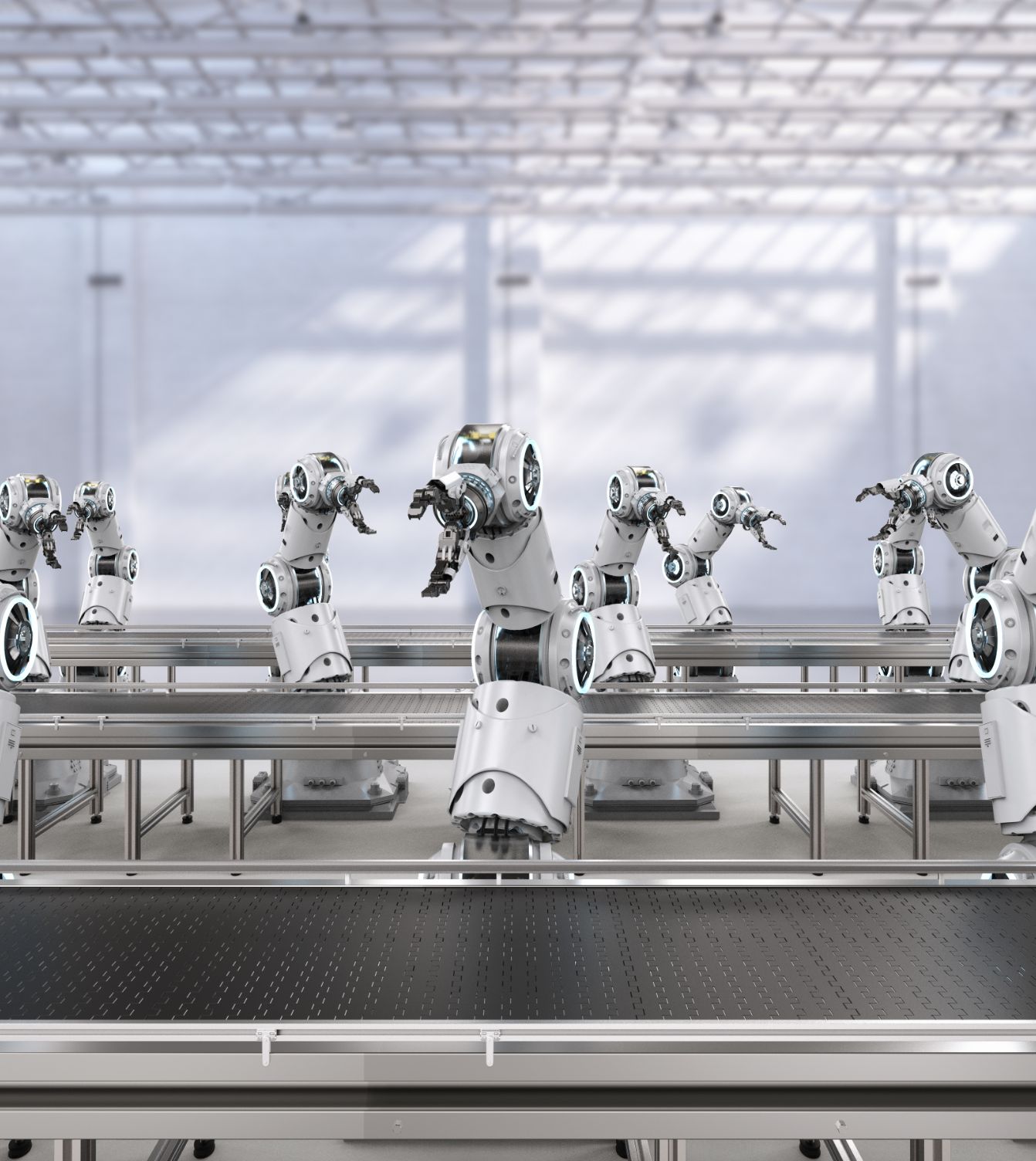

Intelligent Cockpit Production Solution

The automatic assembly line for the central control and instruments of the FHS intelligent driving cabin is compatible with multi-platform products and offers strong flexibility.

Intelligent Cockpit Production Solution

Production Line Highlights

- AGV automatic docking, unmanned material transfer

- Fast and stable production pace, high efficiency

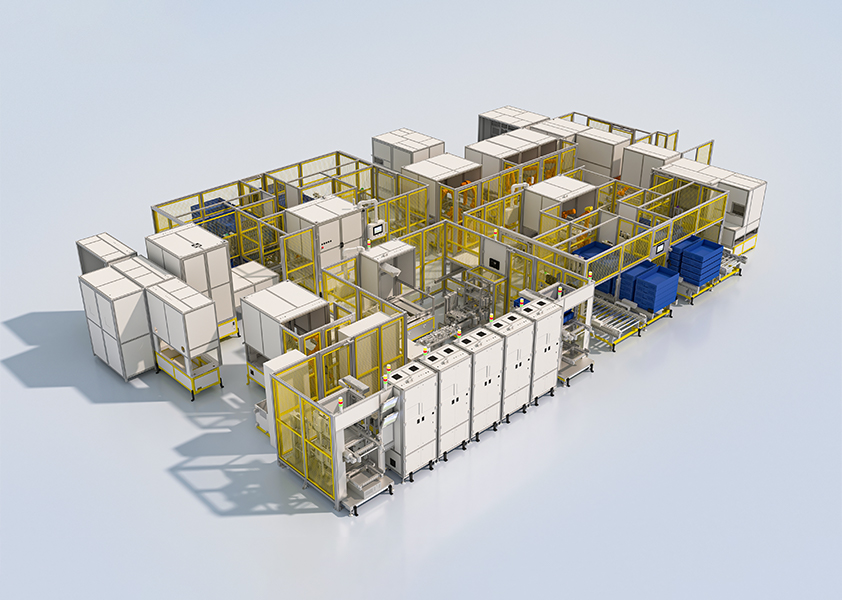

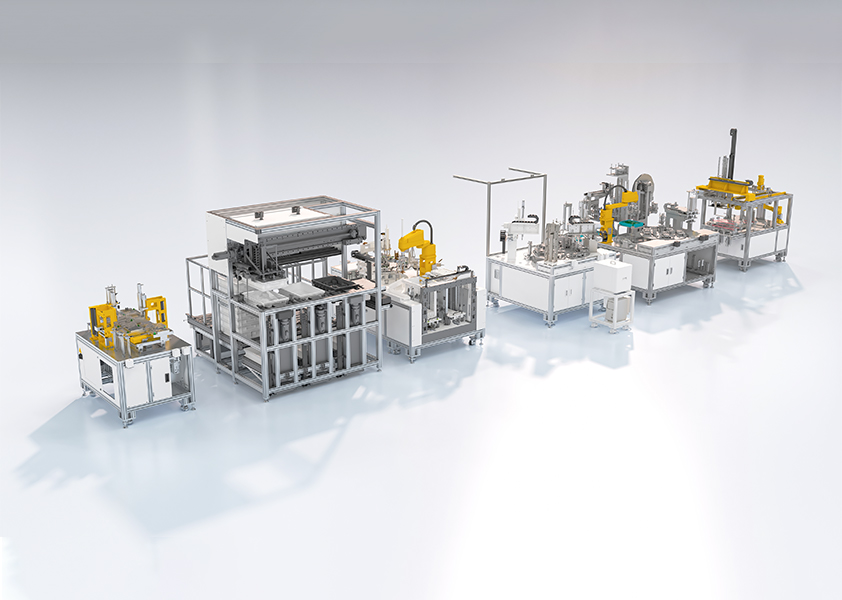

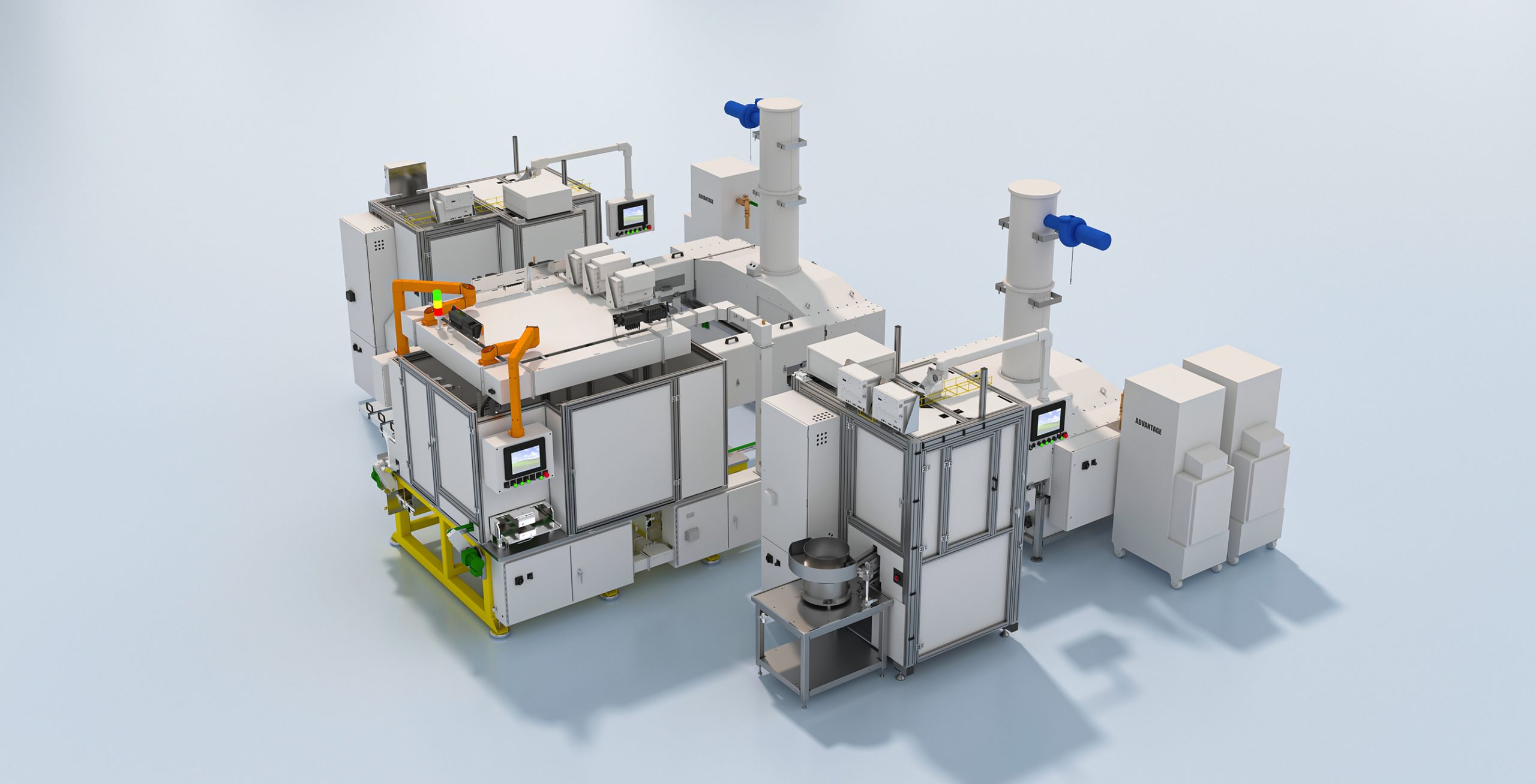

Power System Production Solution

Power System Production Solution

FHS offers production line solutions for power systems, such as electronic water pumps, with extremely high compatibility. These solutions fully consider the needs of customers for various series of products and updates, ensuring high production efficiency and cost reduction.

Production Line Highlights

- The equipment structure is compact. The production line uses a multi-station indexing plate, integrating many stations into one. This design improves the flexibility of the production line and the overall productivity of the line.

- High degree of automation. All parts are automatically installed and inspected for installation quality. The production line uses industrial robots and human-machine collaborative robots to achieve product assembly and transportation.

- High safety standards.

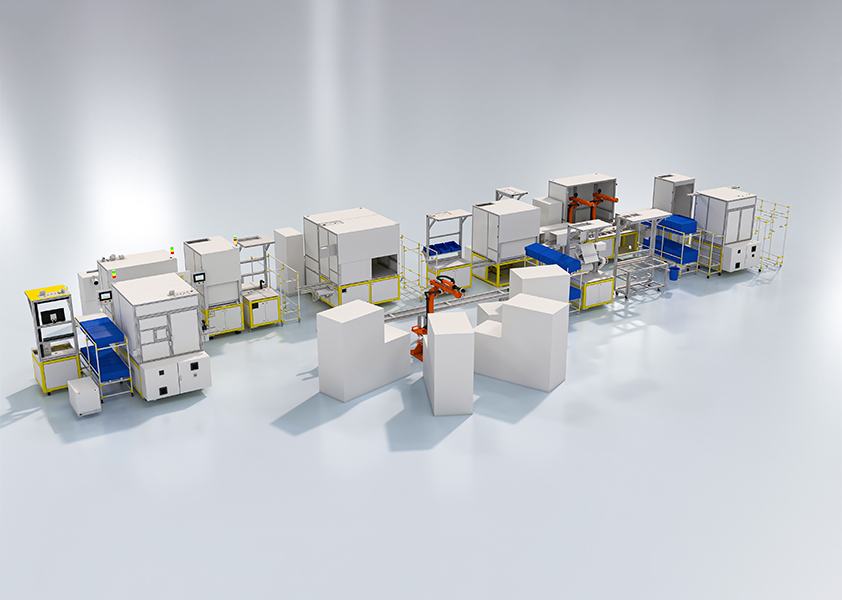

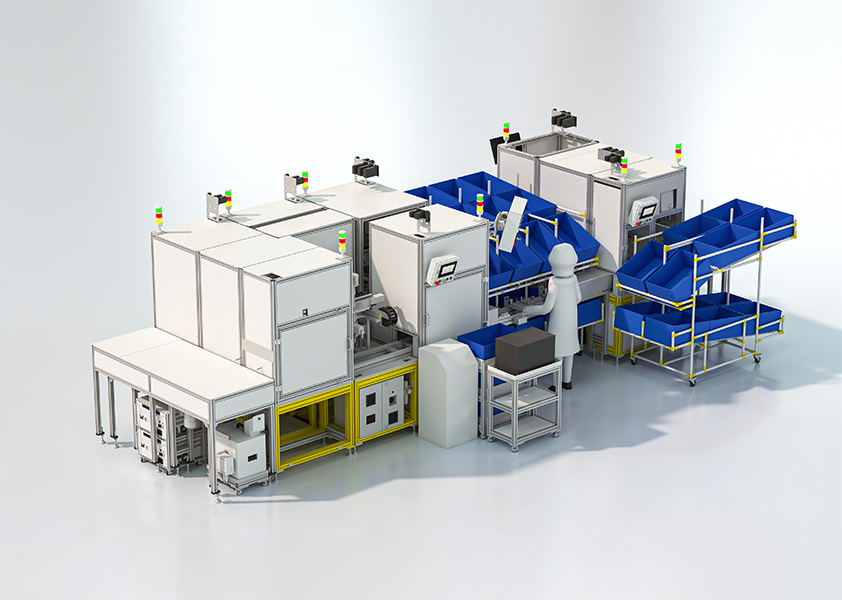

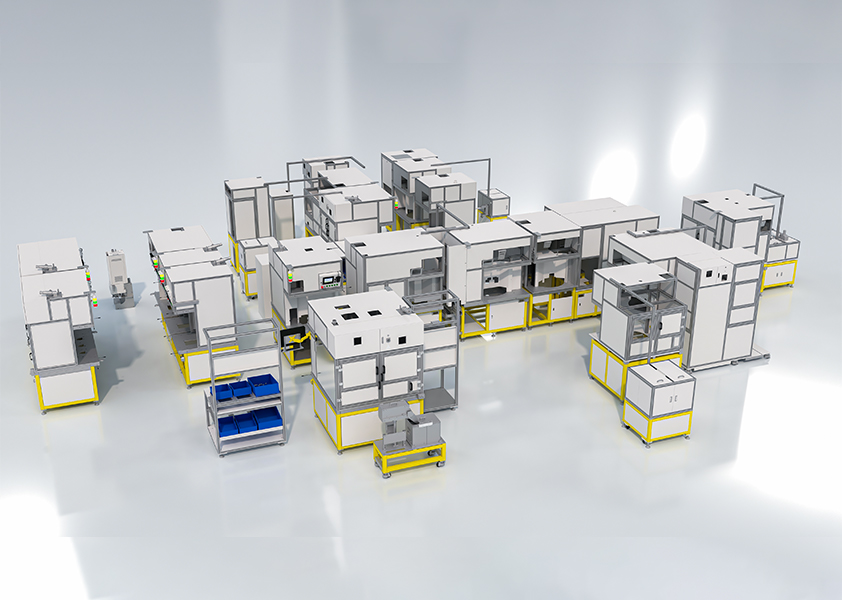

Steering System Production Solution

By adopting modular design and production processes, it is easy to adjust the configuration and production rhythm of the production line, achieve quick switching of production of different products, and enable the production line to respond to the rapid changes and personalized needs of the market. Adopting advanced technology to achieve high-precision and high-quality production of products. At the same time, through information technology and intelligent manufacturing technology, the digitalization and intelligence of the production process can be achieved, further improving production efficiency and product quality.

Steering System Production Solution

Production Line Highlights

- Efficient production efficiency: Through advanced automation equipment, the production line can achieve efficient production efficiency, accurately complete each process, reduce human interference, and improve production speed and output.

- Strict quality control: Advanced testing equipment and processes enable comprehensive monitoring and traceability of product quality, ensuring that product quality and performance meet relevant standards and customer requirements.

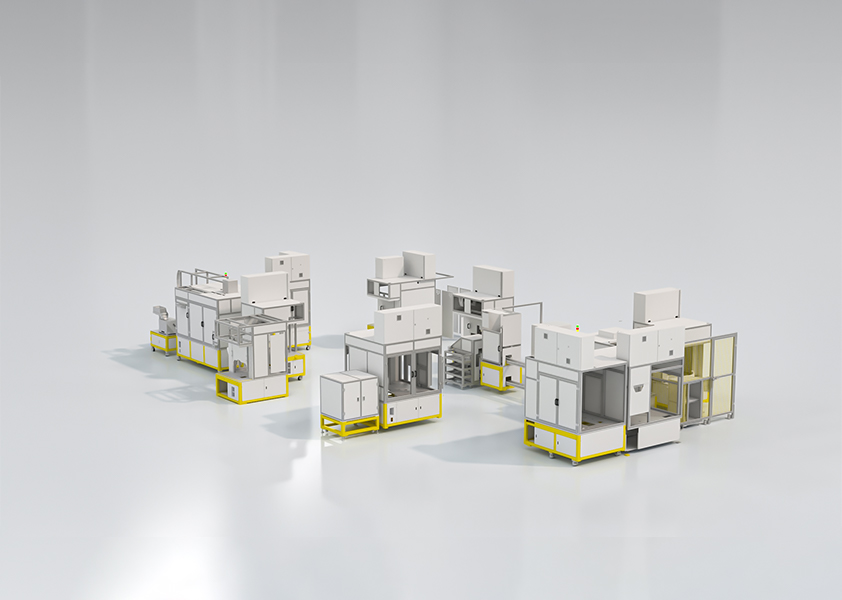

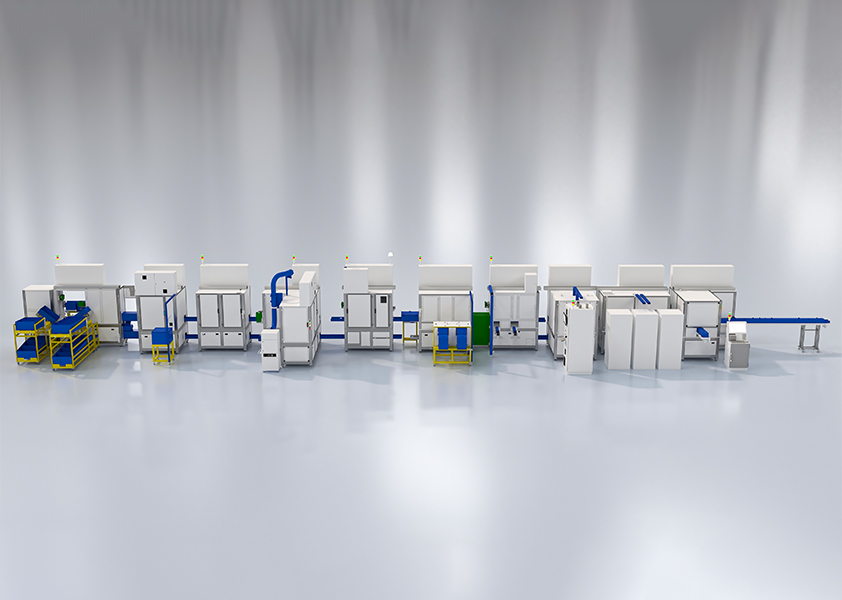

Brake System Production Solution

Brake System Production Solution

FHS provides turnkey engineering solutions for brake system production, utilizing robots, vision systems, tightening guns, AGVs, conveyor lines, and vibrating discs. These automated elements replace manual labor, enhance product precision, reduce production costs, and improve production efficiency, making enterprises more competitive.

Production Line Highlights

- By utilizing automation technology, equipment, instruments, and control systems, the production process of products is automated and assembled to achieve efficient and stable production.

- Achieving automation, continuity, intelligence, and efficiency in the production process creates higher economic benefits.

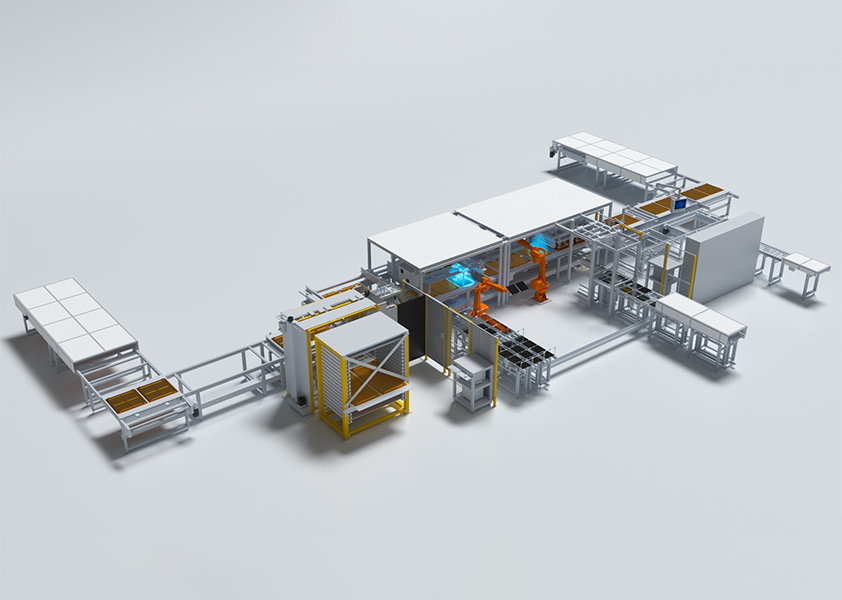

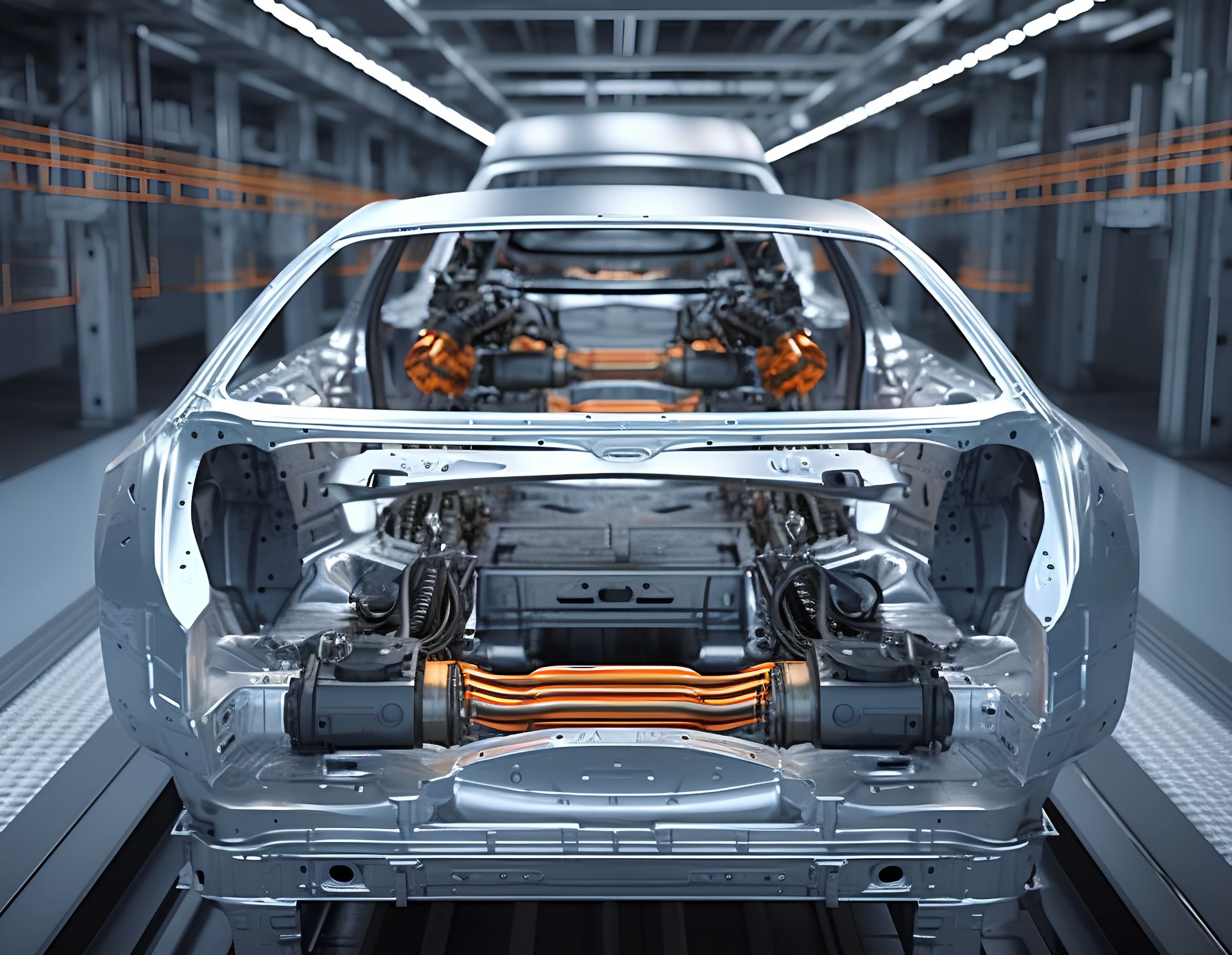

Vehicle Body System Production Solution

The FHS body automation production system is dedicated to researching and providing solutions to various technical challenges, including production capacity, flexibility, accuracy, efficiency, complex forming, and assembly methods. It offers comprehensive solutions that integrate efficient production capacity with flexible production lines.

Vehicle Body System Production Solution

Production Line Highlights

- The equipment has a high degree of automation, and all processes including product loading, assembly, welding, and production are completed automatically;

- Customized design and production of feeding conveyor belts;

- Integrated automatic loading and unloading system, 90 degree angle rotating transmission system, and “double track” continuous motion system, with appropriate tray stopping and lifting functions, allowing for no relative movement between the stationary tray during tray buffering and the continuously moving “double track” belt;

- The equipment adopts an indexing plate to ensure fast and stable operation

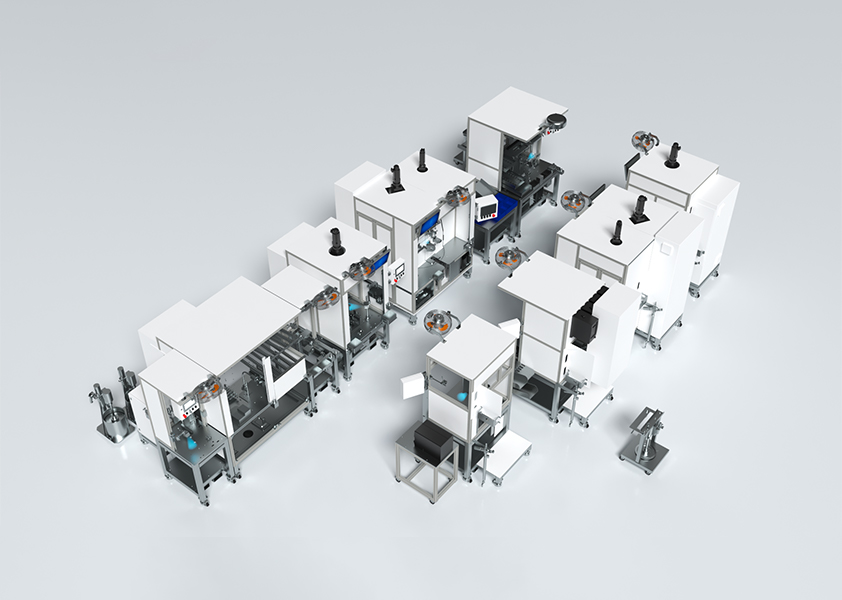

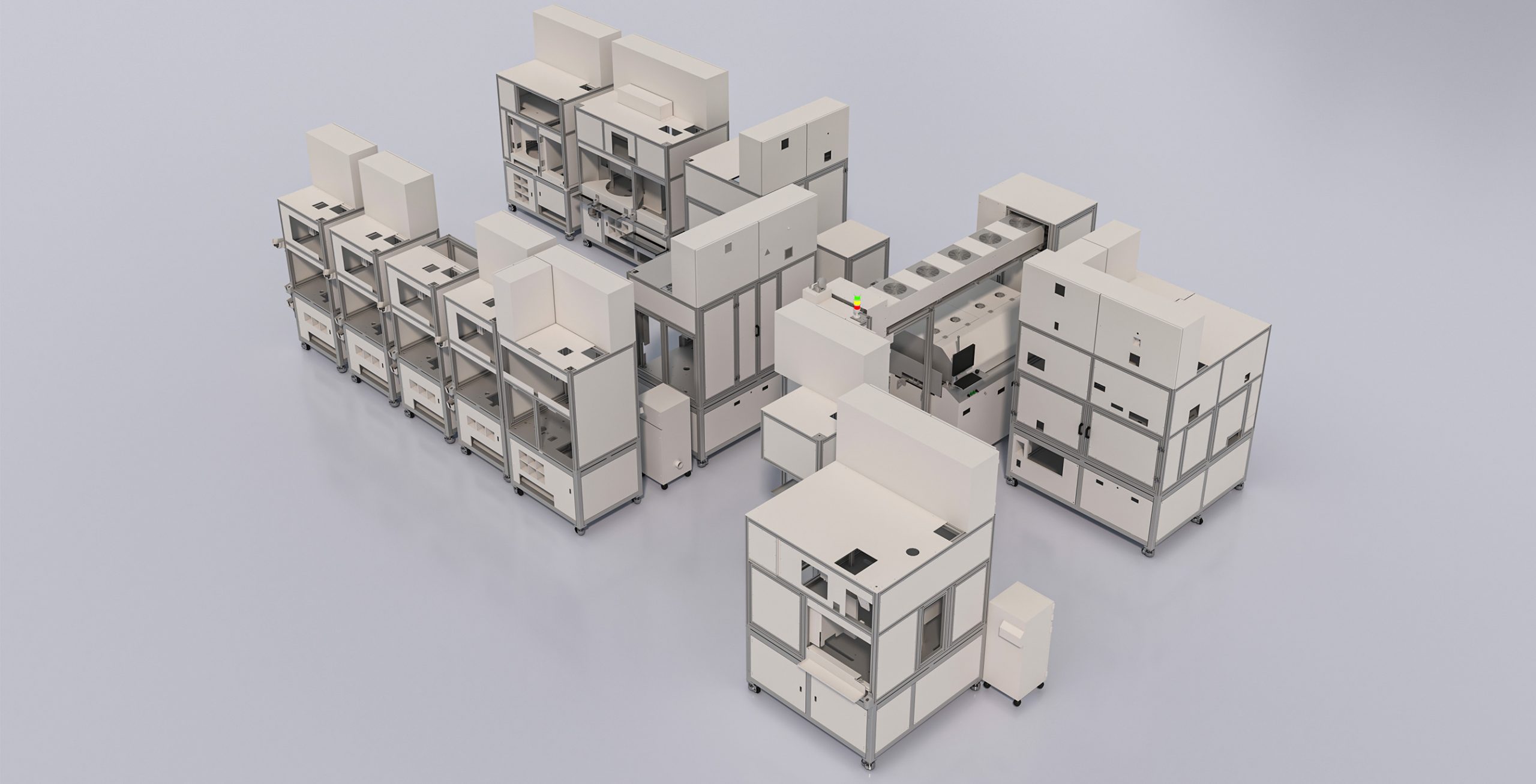

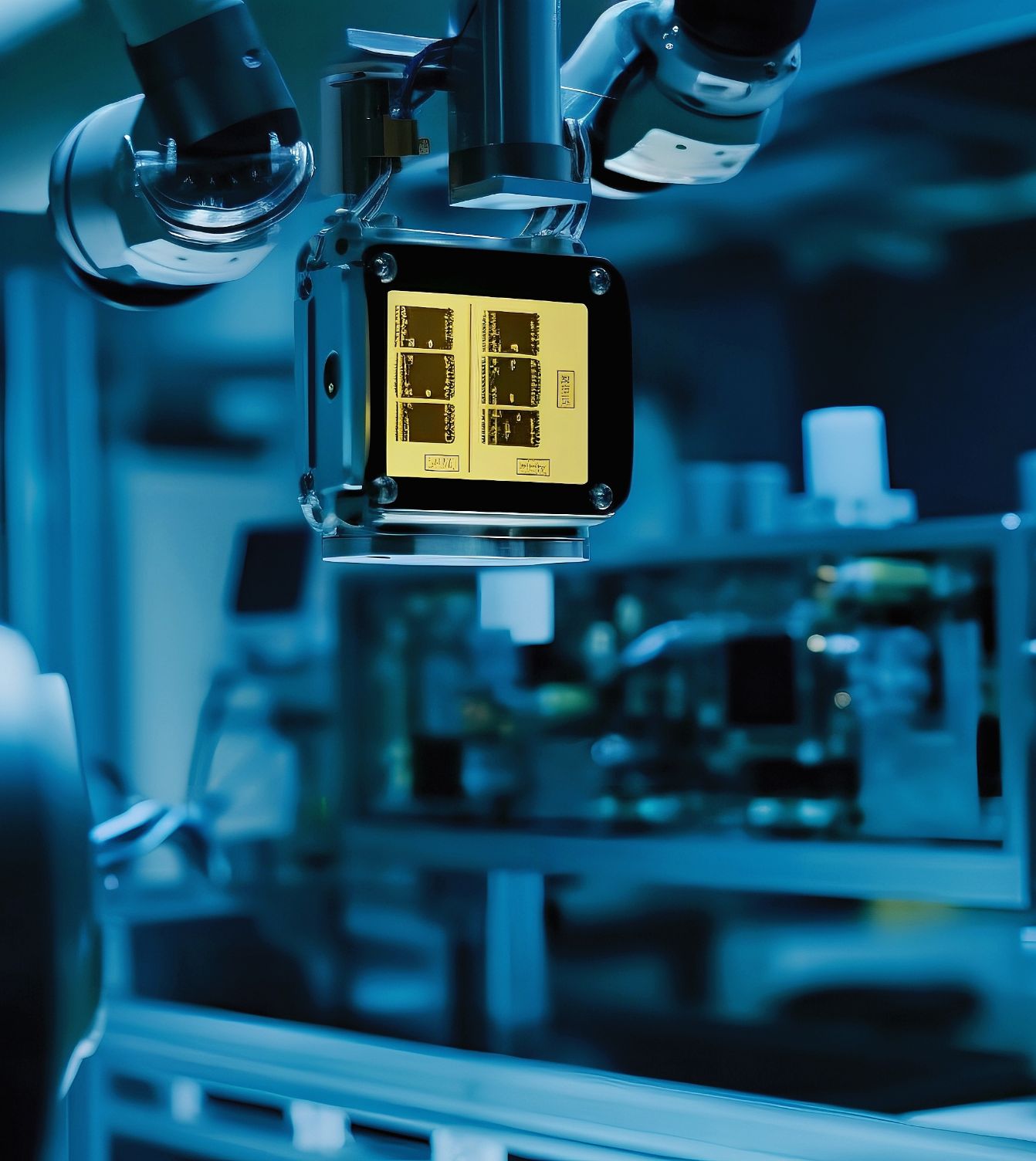

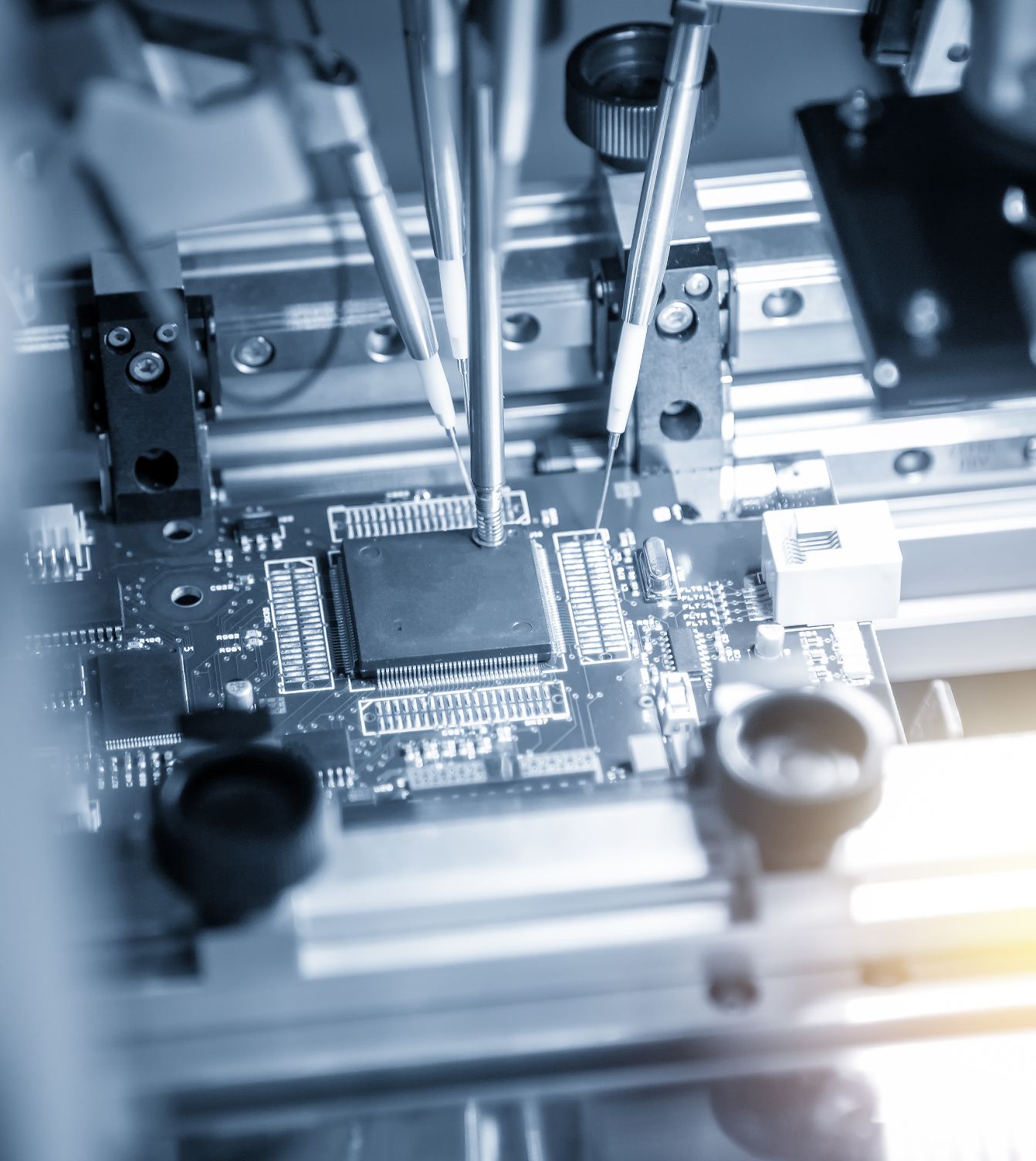

Electrical and Electronic System Solution

Electrical and Electronic System Solution

FHS, driven by technological innovation, introduces advanced production modes and process technologies to optimize industrial structure, improve production efficiency, reduce costs, and achieve the upgrading of automotive electrical and electronic manufacturing.

Production Line Highlights

- The production line realizes full process automation, using multiple robots to cooperate with material transportation to achieve unmanned production;

- A well-designed logistics path layout greatly improves equipment production capacity;

- Multiple workstations adopt a multi workstation turntable design to improve overall work efficiency;

- A single device can complete multiple processes simultaneously, significantly improving production efficiency;

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields