16s

Production Cycle Time

99.8%

Product yield

Introduction

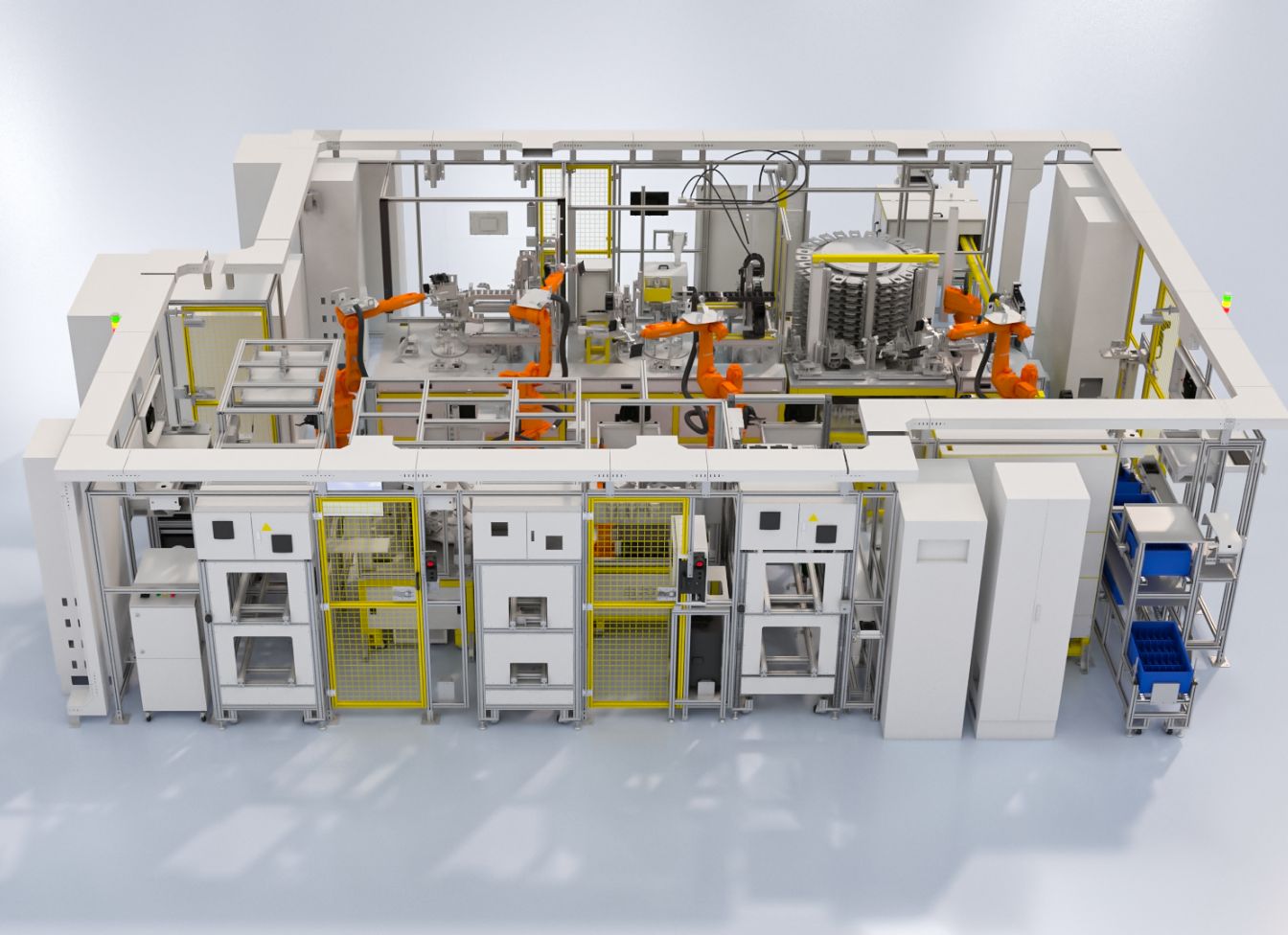

This equipment is an assembly line for body control units, arranged in a circular workstation layout, with four six-axis robots in the middle responsible for product circulation between workstations. The process includes PCB loading, laser engraving, visual inspection, flip and shell assembly, typhoon cleaning, PCB assembly, plasma cleaning, gluing, screw installation, curing, sealing ring installation, EOL testing, airtightness testing, visual inspection of sealing rings, and finished product packaging. The entire assembly process of the body control module is fully automated. Multiple automatic abnormal material output processing ports ensure the continuous and smooth assembly process.

Highlights

- The equipment has been optimized and designed with a reasonable arrangement of workstations and product process flow and transmission methods, significantly improving efficiency.

- Each process mechanism is reliably designed to ensure stable equipment operation.

- The layout of manual operation workstations and operation ports is convenient, ensuring the continuity of equipment operation.

Parameters

Equipment Capacity

16s/pcs

Product Yield

99.8%

Equipment Utilization rate

98%

Overall Size

8900mm×6900mm×2200mm

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields