≥1.67

CMK

≥1.67

CPK

≥80%

OEE

Introduction

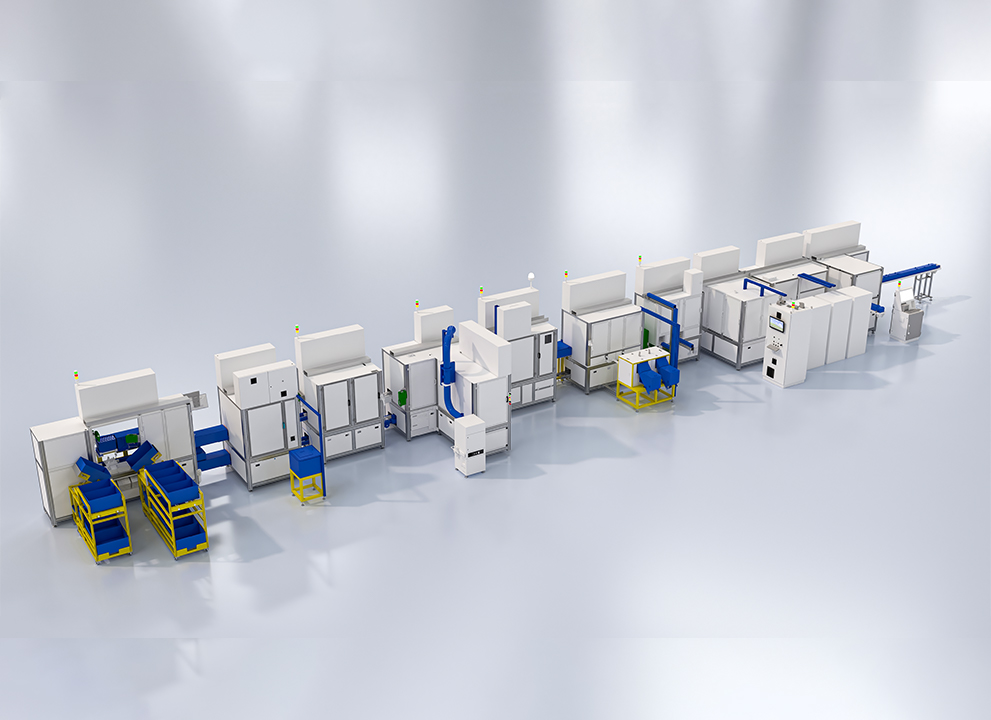

This production line is equipment specially developed by FHS for cooling valve actuators for customers. The equipment functions include pressing, screwing, hot riveting, typhoon cleaning, oiling, sealing ring assembly, ultrasonic welding, laser welding, EOL testing, laser engraving and other processes have been implemented, and a traceability system has been set up for the products, providing reliable and stable support for customers to achieve excellent product quality.

Highlights

- The equipment meets safety regulations and ergonomics, featuring a stable product fixture system, a reliable tightening system, and a dependable product rotation system.

- The accuracy of assembled components meets the precision requirements outlined in the drawings.

- The equipment has a neat and aesthetically pleasing appearance.

- The equipment has been optimized and designed, with reasonable arrangement of workstations and product process flow and transmission methods, resulting in a significant improvement in equipment efficiency;

- The design of each process mechanism is reliable, ensuring the stability of equipment operation;

- The layout of manual operation workstations and operation ports is reasonable, making operation convenient and ensuring the continuity of equipment operation.

Parameters

CT

≤12.4s (excluding EOL CT ≤ 18.5s and hot riveting CT ≤ 16s)

Floor Area

22.5 m*3.6 m

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields