8h

Continuous operation

>98%

Normal operation time

Introduction

The product is manually placed on the equipment,

1) The lining press presses the lining into the lower protective sleeve and presses the bumper extender into the upper clamping sleeve assembly. Automated equipment applies lubricating grease to the upper clamping sleeve and installation bracket, lubricating the installation bracket in 3 places and the upper clamping sleeve assembly in 4 places. The screws are automatically tightened using a tightening gun, and the visual system checks if the installed screws are correct. The upper and lower clamping sleeves are assembled onto the installation bracket, and the component is moved to the next workstation using a dedicated fixture

2) Manually install the lever, apply lubrication to the rake and mounting bracket, install springs, lever components, cams, buffers, bevel washers, bearings, flange nuts, etc., completing the installation of the upper jacket

3) Press the bearing onto the lower shaft using a press machine, apply lubricating grease, and perform a sliding load test

4) Install the shaft onto the jacket using a press, tighten the lower bearing, and press the shaft assembly into the upper jacket assembly

5) Connect the shaft assembly to the column assembly and conduct testing

Highlights

- High installation accuracy, with full monitoring of clamping force and dimensions throughout the process. This results in a high yield, reduces enterprise costs, increases the market share of enterprise products, and boosts enterprise profits

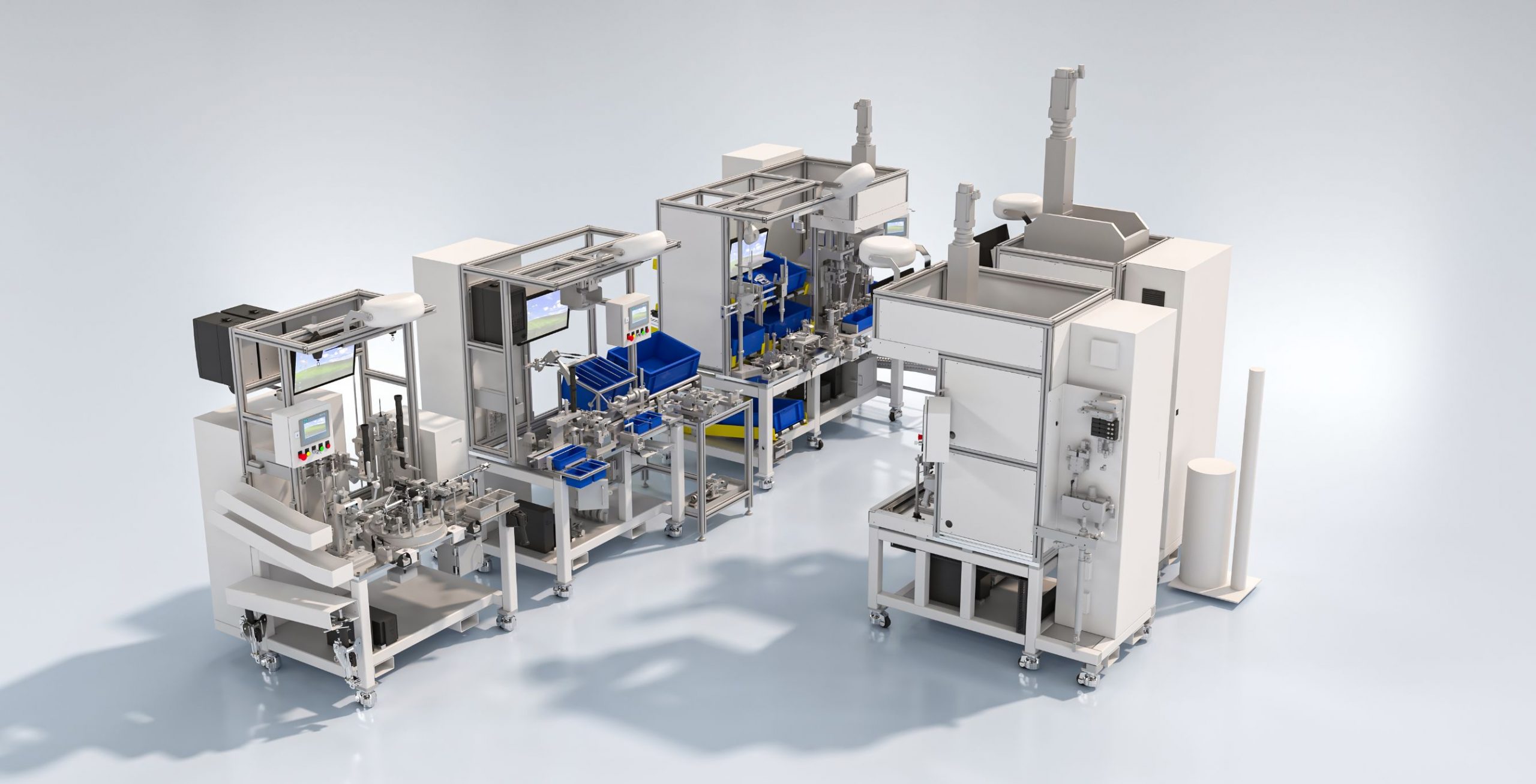

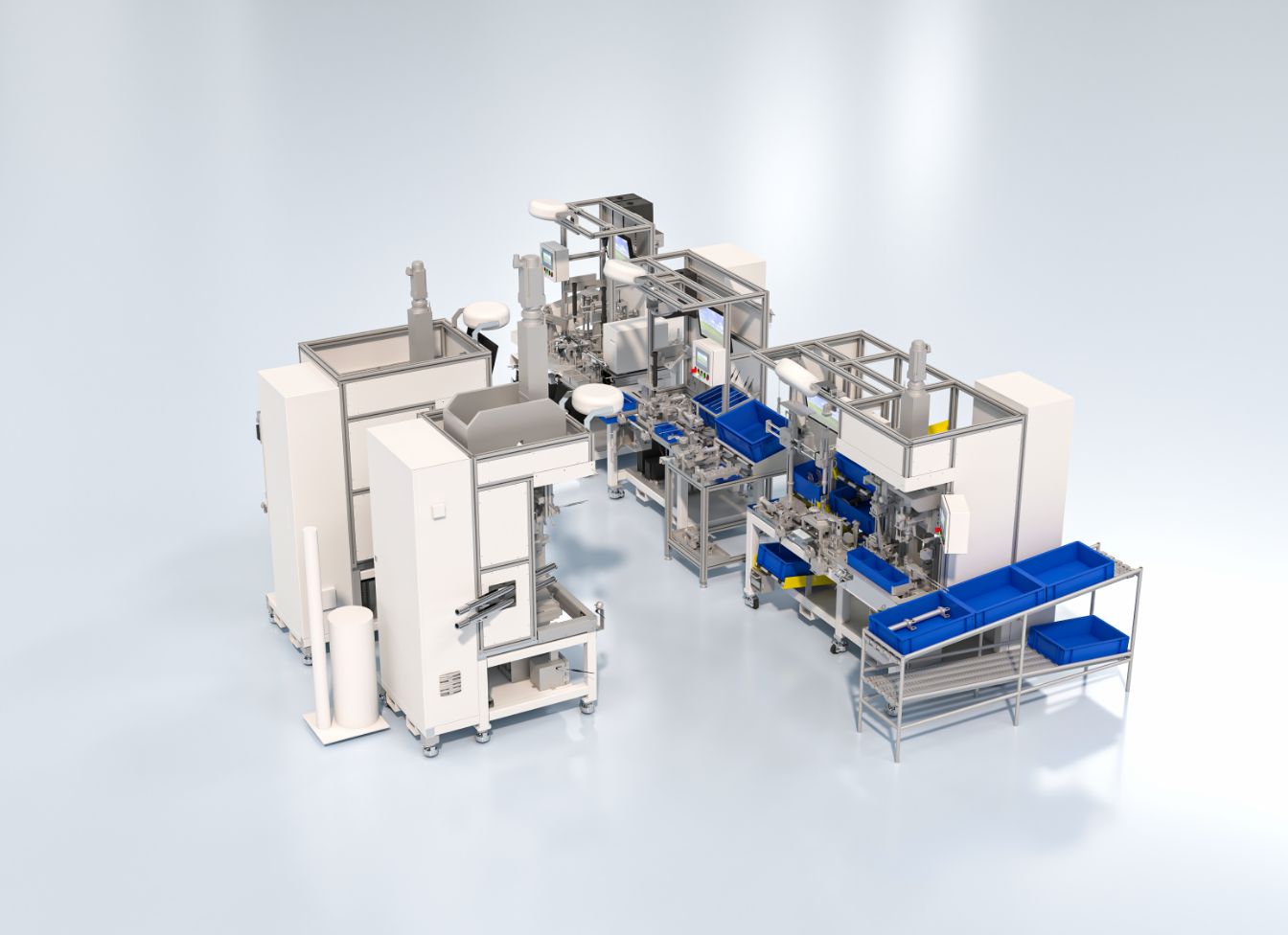

- The entire line occupies a full area with high space utilization, and the floor area size is 6.4 m x 5.5 m

Key Performance

- Continuous operation for 8 hours, normal operation time>98%

- The equipment runs continuously for 4 hours or 125 pieces per fixture (whichever is higher). Throughout the entire operation process, the operating parameters remain unchanged, the equipment has good stability, and no faults occur

- This automated production line has low personnel investment, high production efficiency, and high installation accuracy

Parameters

Weighing Sensor Straightness

Straightness<1% (full size), Accuracy < 2% (full size)

Straightness of Pressure Position

Straightness < 1% (full size), Accuracy ≤ ± 0.03 mm

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields