≥1.67

CMK

≥1.67

CPK

≥80%

OEE

Introduction

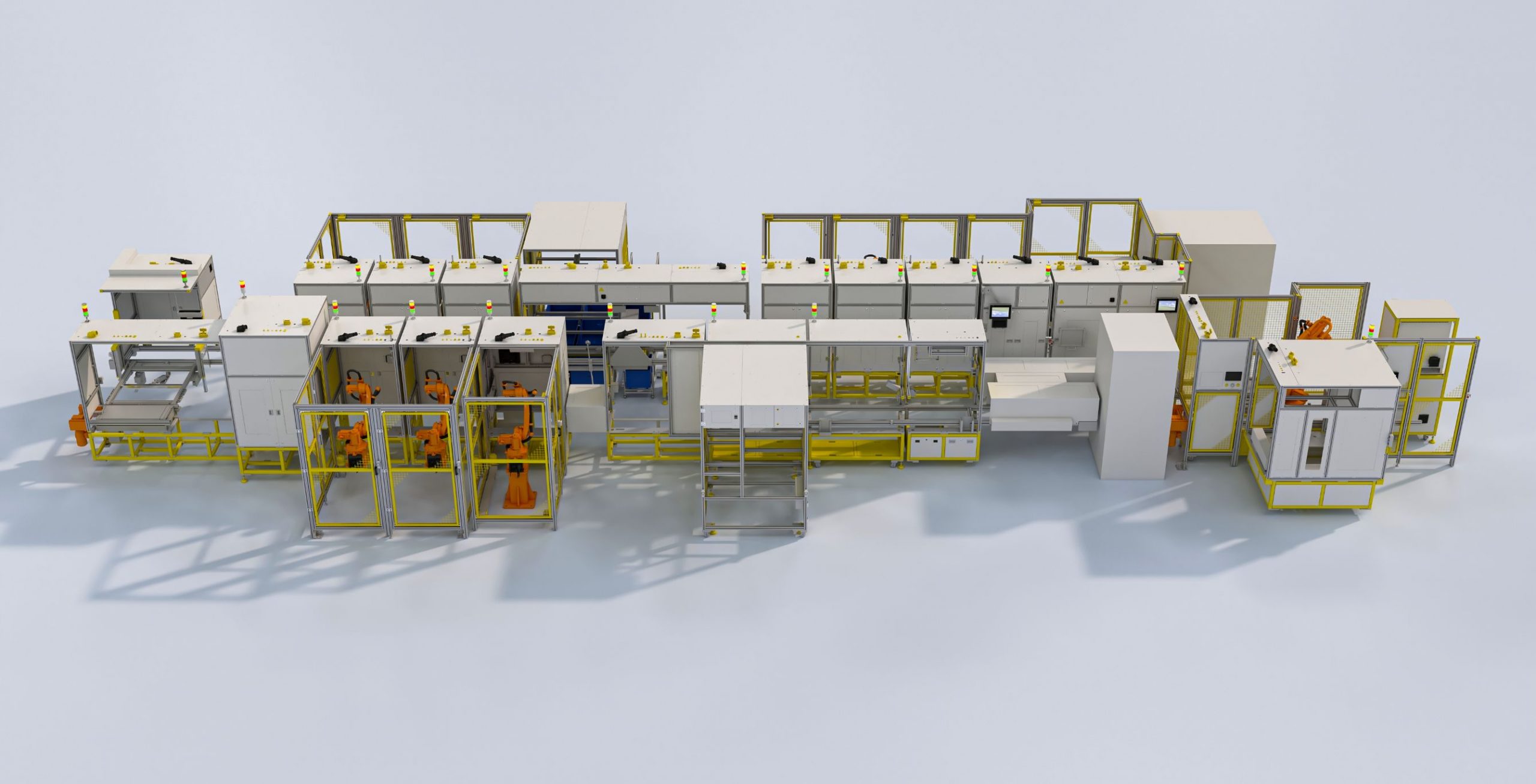

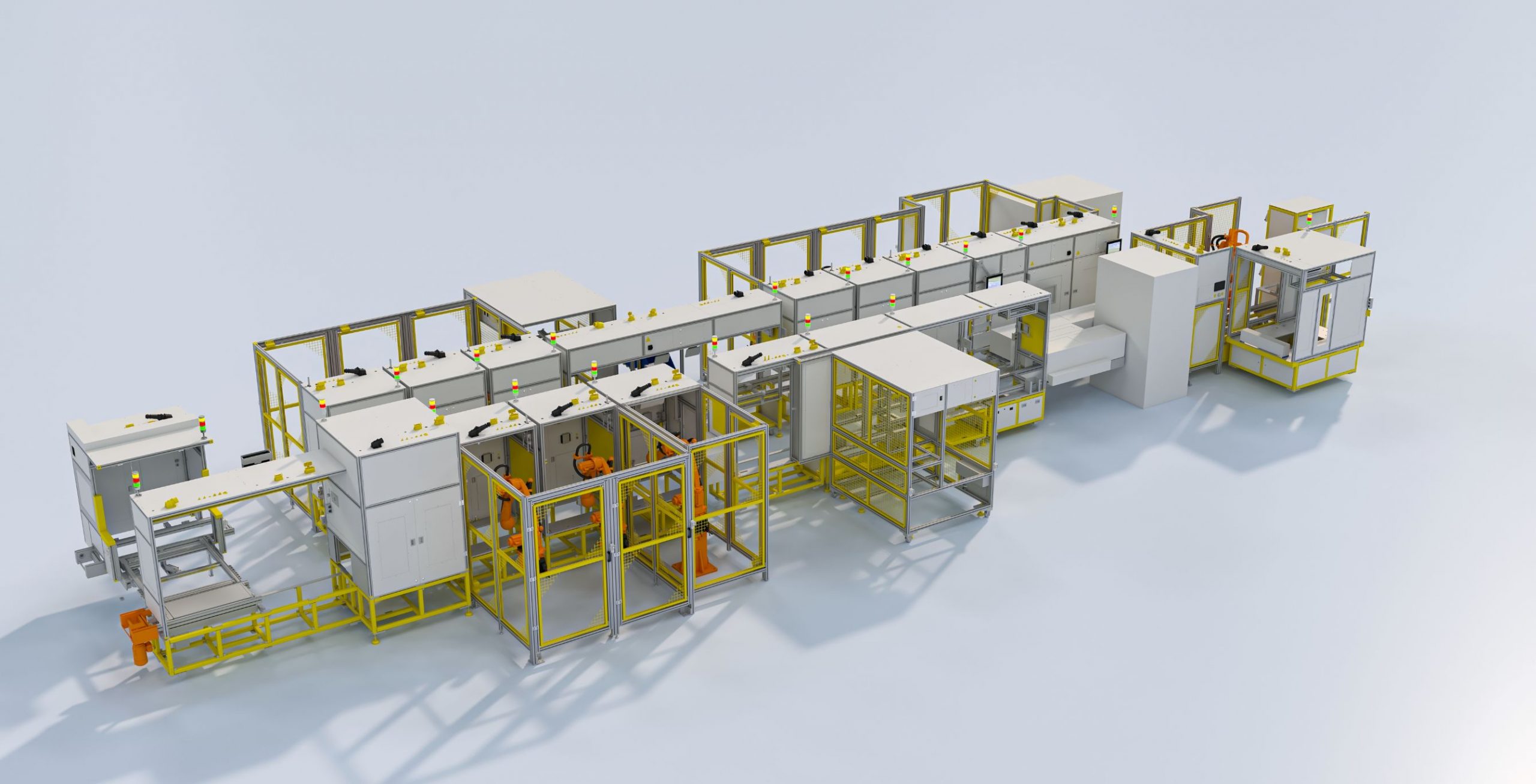

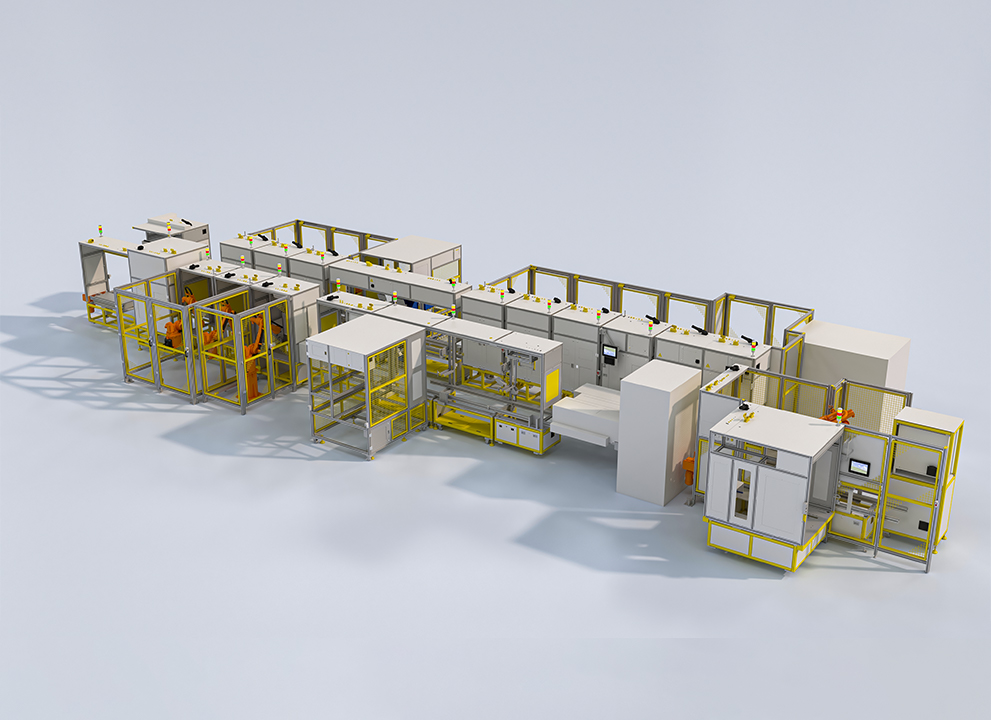

This is used for the central control and instrument assembly of intelligent driving cabins in automobiles. The device automatically interfaces with AGVs to achieve automatic loading and unloading of materials and transfer. It features automatic loading and assembly of the display and rear cover, flexible assembly inspections for the fan and FPC, visual position-guided robots for automatic product tightening, a three-axis servo system for visual-guided gluing, and 3D vision for fully automatic detection of screen assembly gaps and height differences.

Highlights

- AGV automatic docking, unmanned material transfer, vision-guided robot automatic assembly, tightening, and gluing, 3D camera inspection of product size, screw tightening displacement and torque curve monitoring, gluing accuracy of 0.01g, visual detection of gluing shape, robot flexible quick change system, tray work automatic type change.

Parameters

CT

37S

One-time pass rate

99.5%

Non-first changeover time

1H

Screw tightening torque

1.4NM

Overall size

35000mm*9000mm*2800mm

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields