2.2s

Production cycle time

Introduction

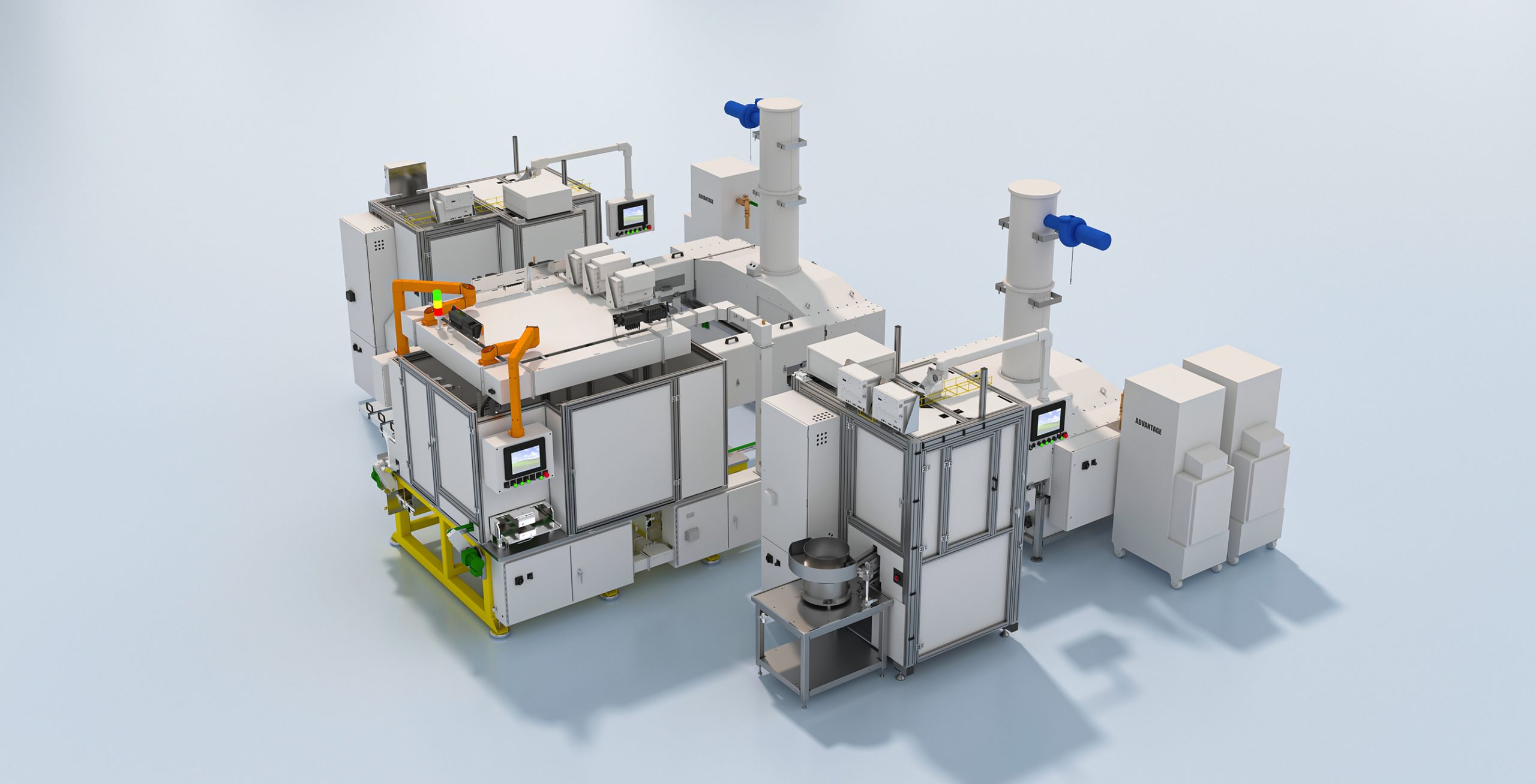

This equipment is mainly used for the assembly of igniters. The assembly process employs a dividing disc method for workstation assembly, with line transportation used for transferring products between equipment. Products are automatically loaded using a vibration disc and then enter the sizing station, where slurry is automatically added and relevant processes are completed. The products are then automatically transferred to the oven station for solidification. Subsequently, core pressing and welding are carried out sequentially. Finally, the product undergoes helium inspection testing to ensure quality.

Highlights

- The fully automatic production line operates without manual intervention, utilizing an indexing plate for internal transmission to ensure product speed and stability. Transmission between equipment uses a tooling line body method, integrating processes such as automatic feeding, sizing, oven curing, welding, and helium inspection. The equipment operates stably and maintains high consistency

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields