24s

Cycle time (mechanical and manual)

>99.9%

FPY

≥85%

OEE

Introduction

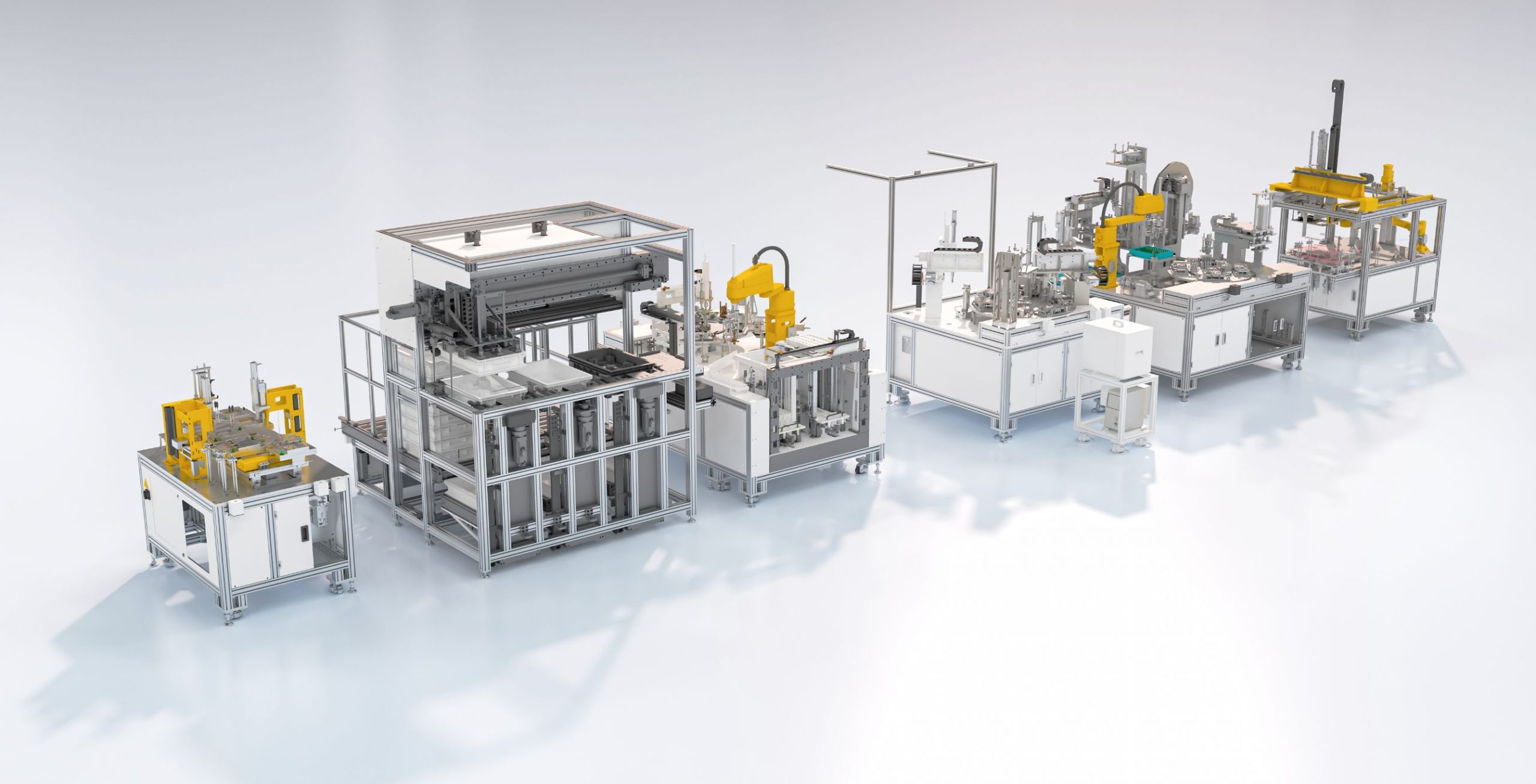

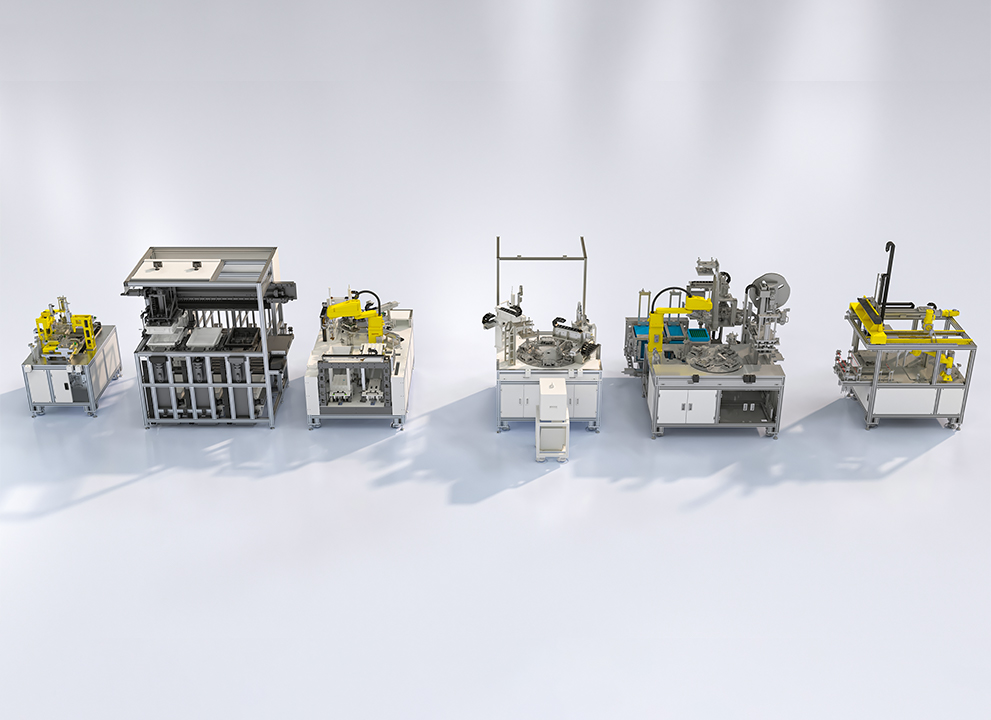

The entire production line adopts the design principle of Smart Line, with each piece of equipment arranged in the order of the process. The workpieces are transferred using a 6-axis robotic arm, and the a AGV cart is used for loading, achieving automation of the production line;

The device does not require a frame, making it easier to transfer workpieces;

Workpieces are transferred through industrial robots, and safety is ensured using safety scanners and access controls, eliminating safety hazards on the production line. The production line is compatible with four models across two major categories of products.

Highlights

- The entire line only requires one operator, with a high degree of automation, reducing personnel participation and labor costs. The overall space utilization rate of the line is high;

- The production line equipment has energy consumption monitoring and data collection functions;

- The entire line features high-definition video displays such as animated demonstrations, virtual simulations, and physical shooting;

- The points of all electric cylinders and robots on the entire line are displayed on the HMI, and can be manually set through the HMI interface;

Parameters

Cycle Time (mechanical and manual)

24s

FPY

>99.9%

The entire line land occupation size

15m*7m

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields