Enhancing managerial effectiveness is essential for achieving annual operational goals. FHS Group recently reached an important milestone with the completion of its Leader Transformation Plan—Workshop for Periodic Team-Based Learning (TBL).

Ms. Cao Juan, deputy general manager of operations, kicked off the session with an opening speech.

“When setting goals, a team must recognize the importance of continuous learning and practice. As team leaders, we need to adopt advanced methods, learn from past experiences and bring out each member’s strength to achieve team goals more efficiently.” Ms. Cao also emphasized the critical role leaders play in team development. “Our actions set the tone for our teams, and the impact of strong leadership cannot be underestimated. In future, we will prioritize connecting theories with practice to enhance overall team efficiency.”

Key Points Review

Before diving into new topics, the participants reviewed the previous main points and summarized lingering questions. This approach reinforced earlier lessons and set the stage for in-depth learning.

Why Systems Thinking Matters for Leaders

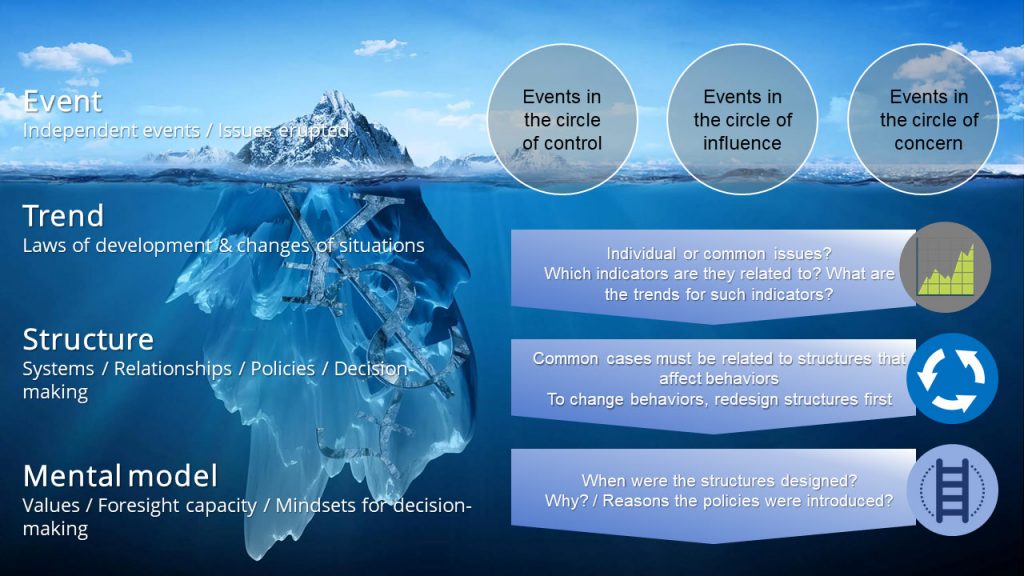

Led by Ms. Jin, participants analyzed the goals, events and concerns through practical cases. They explored solutions using the iceberg model and discussed the potential trends and side effects. During the process, the participants found that their solutions might not be perfect and even bring new challenges on many occasions.

Why Systems Thinking Matters for Leaders

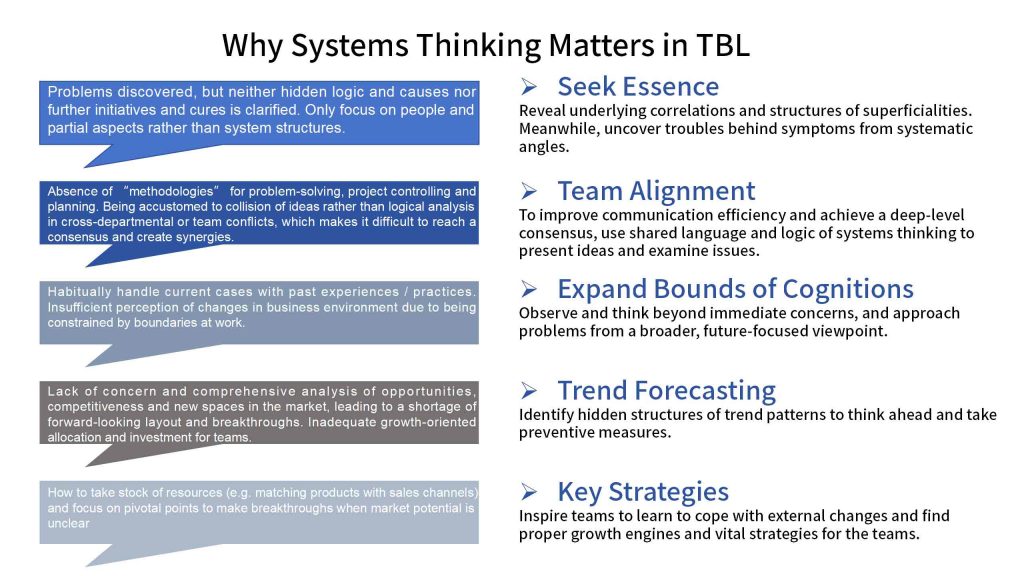

The following aspects were introduced by Ms. Jin when explaining the significance of systems thinking:

Seek Essence: Reveal underlying correlations and structures of superficialities. Meanwhile, uncover troubles behind symptoms from systematic angles.

Team Alignment: To improve communication efficiency and achieve a deep-level consensus, use shared language and logic of systems thinking to present ideas and examine issues.

Expand Bounds of Cognitions: Keeping observing and think beyond immediate concerns, and approach problems from a broader, future-focused viewpoint.

Trend Forecasting: Identify hidden structures of trend patterns to think ahead and take preventive measures.

Key Strategies: Inspire teams to learn to cope with external changes and find proper growth engines and vital strategies for the teams.

Through dissection of practical cases in the workshop, the leaders understood the ways to analyze and solve problems with systems thinking and realized the limitation of linear thinking. Ms. Jin guided the participants to determine root causes of matters from systematic angles, which both assisted in the addressing of current events and provided new ideas on preventing troubles proactively.

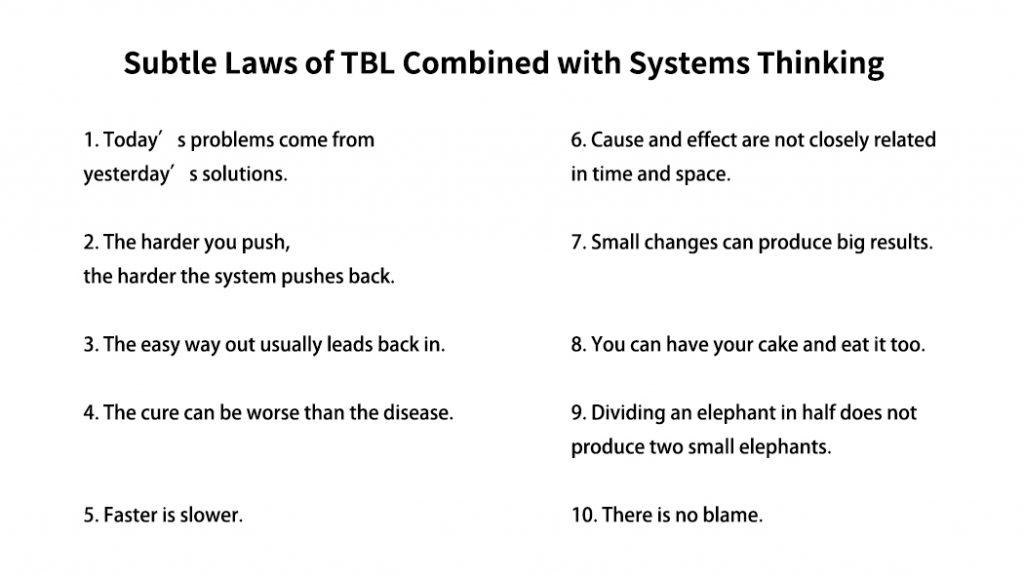

Subtle Laws of Systems Thinking

These principles provided participants with a fresh perspective on leadership. “Today’s problems come from yesterday’s solutions”, “the harder you push, the harder the system pushes back”, “there is no blame” and other rules remind the leaders to take the long view, avoid short-sighted solutions and excessive interference. Connect theory and practice will contribute to making wiser decisions in work.

Summary Speech by Representative

As the course drew to a close, Dr. Huang Fuchang, product director of magnetic levitation from the research institute shared his thoughts,

“This program has helped us see how different models and theories are interconnected. For example, PDP models as well as systems thinking emphasize the importance of understanding individual personalities and tailoring management techniques accordingly. The mind drives actions, which can lead to both positive outcomes and potential side effects. Additionally, the workshop deepened our appreciation of the connections between knowledge and theories across various fields. The lecture further sparked our curiosity and inspired us to apply in practice. The knowledge and methods we gained not only improve our management capabilities, but also help us address engineering challenges more effectively.”

The workshop provided an opportunity for the leaders to thoroughly study the theories and practice of TBL, experience the power of systems thinking, master the approaches to examining issues from broader standpoints and learn how to find more effective strategies with teams. By meticulous analysis of the examples, the participants recognized the limitation of linear thinking and acquired skills to explore the root causes of challenges at a systematic level. The techniques empowered the leaders to address current issues and provided innovative thinking for prevention. The profound and refreshed understanding strengthened the participants’ confidence in the power of systems thinking and TBL, enabling them to respond to challenges more effectively and drive the growth of individuals and organizations.

Conclusions

The Leader Transformation Plan has successfully concluded. FHS group will continue to develop a human resources management system aligned with its strategic goals. Guided by the vision of “becoming a prestigious global smart manufacturing enterprise”, the Group will strive to explore the path of talent cultivation; adhere to goal orientation, problem orientation and result orientation; increase managerial effectiveness and optimize management approaches, systems and mechanisms to boost high-quality development.

Based in East China,

Reaching Out Worldwide

FHS Group is based in East China, with a global layout. FHS Group has after-sales service outlets and partners in many countries and regions around the world, and has set up subsidiaries in the U.S.A., Germany and Hungary, and maintains after-sales team and partners in France, Spain, the Czech Republic, Romania, Mexico, Poland, Hungary, South Korea, India and other countries.

Leading in Intelligent Manufacturing

and Multi-Industry Development

Founded in 2010 and headquartered in Kunshan, Jiangsu Province, FHS Group is a global one-stop smart manufacturing solution provider. There are more than 2,000 employees, of which R&D team accounts for more than 60%. The business scope covers new energy, auto parts and life sciences and other intelligent manufacturing fields, providing intelligent, digital, flexible intelligent manufacturing production solutions and core equipment data services.

Continuous Management Optimization

for High-Quality Industry Development

FHS Group is committed to promoting digital, modular and lean management. We have a strong grasp of a number of core technologies, including control perception, laser processing technology and digital information technology. This allows us to consolidate our absolute competitive advantage as an enterprise. By continuously enhancing systematic management and optimizing our supply chain, project management, and talent development systems, we support rapid business growth. We are dedicated to breaking new ground in cutting-edge technologies and exploring innovative solutions in intelligent manufacturing, driving high-quality development across the industry.