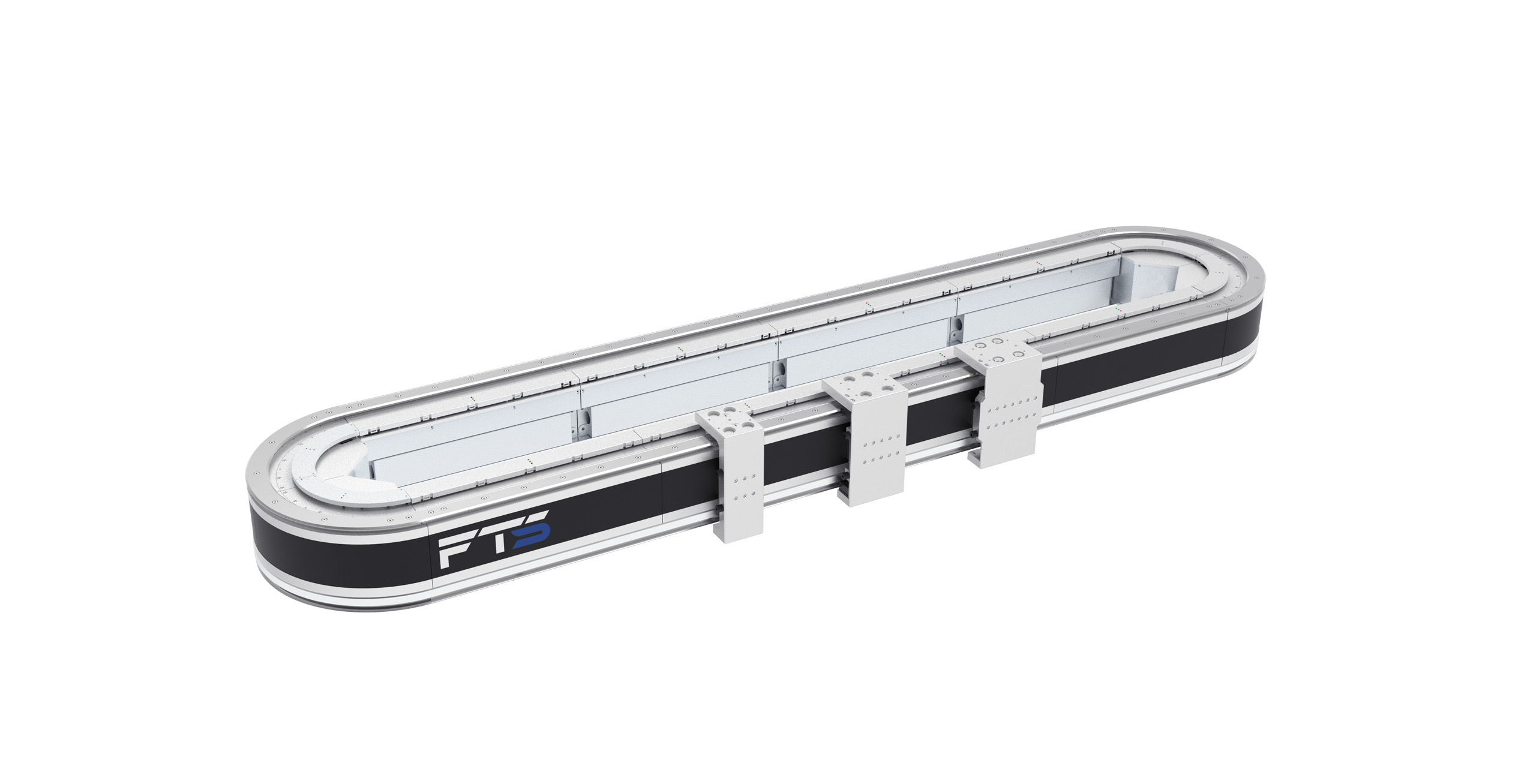

±0.1 mm

Repetitive positioning accuracy

5 - 40 kg

Load range

100 N

Max. Thrust

2.5 m/s

Max. Speed

Product Highlights

- Flexible combination with the FTS – MT line

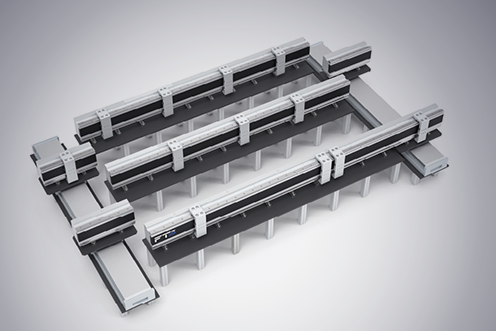

- Flexible layout which can be with horizontal or(and) vertical structure

- Quick mover and tooling replacement for different product types

- Modular design adapts to various production needs

- Customizable workstations with expandable motor integrated modules and movers

- Designed for long-term use with multiple product iterations and process upgrades

Application cases

Design Focus: Assembly of prismatic battery modules.

Features: Maglev transport system for high-speed transfer of water cooling plates;

Integration with AGVs for material handling.

Key Processes: unpacking, sorting, and barcode scanning of cells and cooling plates;

Cell OCV testing, glue application and inspection, modular assembly into beams, automatic water pipe connection, stack formation into battery blocks.

Compatibility: Support various cooling plates within the size range of 800-1500mm.

Advantages:

Adjustable spacing, infinitely variable, no need for fixtures;

Facilitated cooling plate replacement by quick parameter change.

Design Focus: A transfer solution for semi-finished new energy vehicle displays moving between workshops.

Features: Integrated with air knives, isolation doors, and safety light grid;

Equipped with multiple manual workstations and safety zoning;

Meets ISO Class 7 cleanliness requirements.

Advantages:

Achieve cleanliness up to ISO Class 6;

Independent mover control, safety zone implementation;

Upon triggering the safety light grid, the affected zone stops, without affecting other areas.

| Cycle time | 11 sec |

| Cleanliness | ISO 6 |

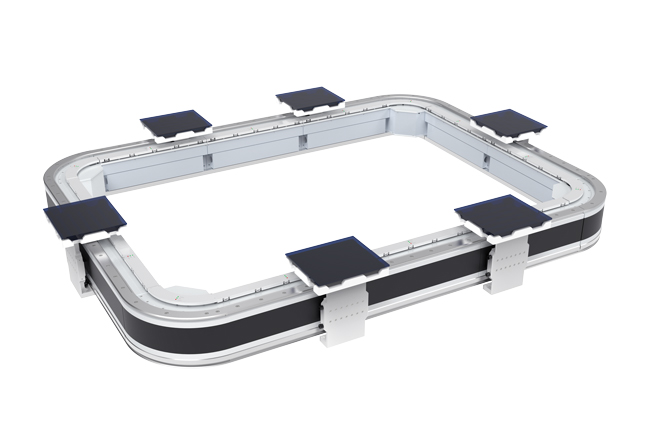

FTS - MT Lite Motor Integrated Module Parameters

| Motor integrated module | C050 | ||

| Magnetic plate width (mm) | 80 | 120 | 160 |

| Peak thrust (N) | 50 | 75 | 100 |

| Motor integrated module | C050 | ||

| Magnetic plate width (mm) | 80 | 120 | 160 |

| Peak thrust (N) | 50 | 75 | 100 |

FTS-MT Lite Basic Parameters

Typical load

≤40 kg

Max. Speed

2.5 m/s

Repetitive positioning accuracy

±0.1 mm

Power supply voltage

DC 48V

Configuration software

iFTS-Studio

Communication interfaces

EtherCAT Modbus/TCP PROFINET CC-Link CANopen POWERLINK

Max. Number of modules

255

Max. Number of movers

255

Production line expandability

Both software and hardware support modular expansion

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields