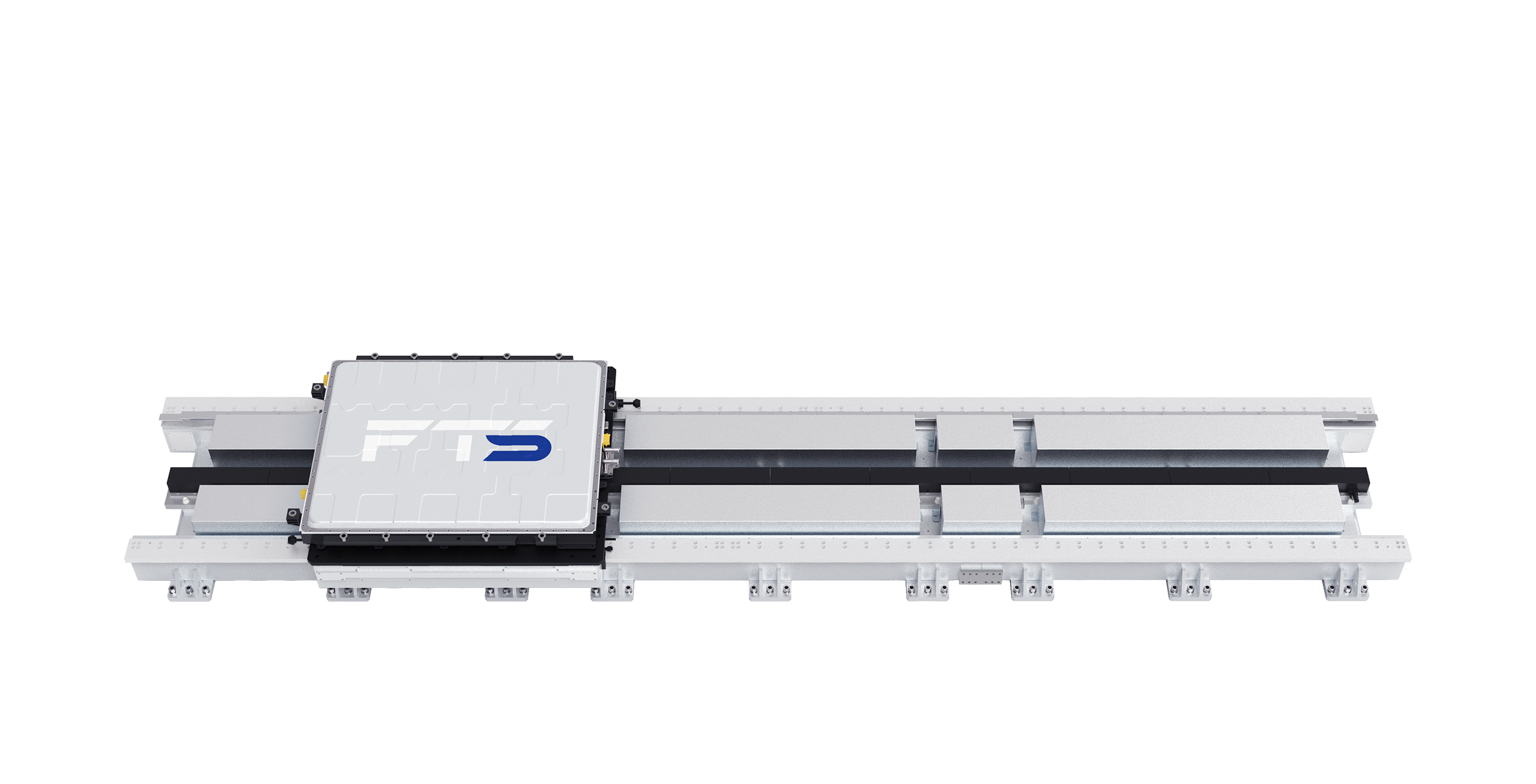

±0.1 mm

Repetitive positioning accuracy

150 - 5000 kg

Load range

3.5 m/s

Max. Speed

Product Highlights

- Spaced motor arrangement improves efficiency and utilization

- Supports heavy loads up to 5000 kg

- Quick mover and tooling replacement for different product types

- Modular design adapts to various production needs

- Customizable workstations with expandable integrated motor modules and movers

- Designed for long-term use with multiple product iterations and process upgrades

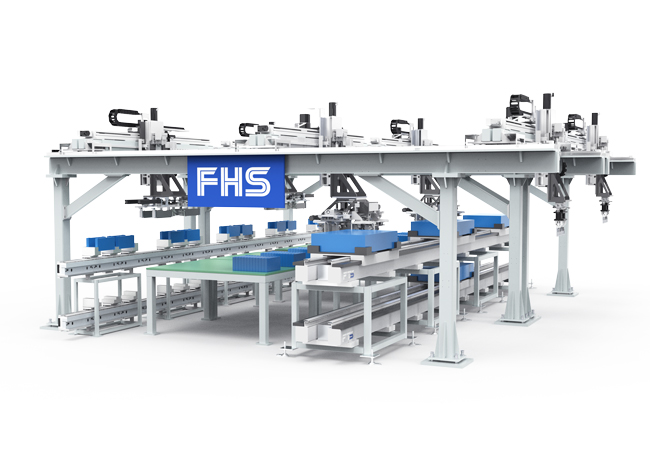

Application cases

Design Focus: A body-in-white welding solution boosts productivity, lowers operating costs, and enhances safety for automotive manufacturers.

Features: Compatible with all body manufacturing processes;

Accommodates non-standard chassis dimensions;

Supports multiple vehicle types, including gasoline, hybrid, and electric models.

Advantages:

Speed and Efficiency: The transfer speed of this system is double that of traditional systems, resulting in a 25% increase in hourly output;

Space Optimization: Reduction of the car body shop floor area by 30%;

Reliability: It has a nearly zero failure rate, with an uptime of up to 98%, which is 10% higher than traditional systems;

Versatility: It is well – suited for all body manufacturing processes and can support multiple vehicle types, including gasoline – powered, hybrid, and electric vehicles;

Cost Savings: Energy consumption is reduced by 24%, and the system requires minimal maintenance;

Safety: Elimination of the risks associated with traditional roller wear, grease, and other contaminants.

Design Focus: Assembly of automotive power battery modules.

Features: Maglev technology for efficient cell and module transport;

AGVs for automatic cell loading.

Key Processes: OCV testing, insulation sheet application, insulation sheet stripping, and module stacking.

Advantages:

Streamline station complexity, reduce commissioning challenges and duration;

Reduce transport and secondary positioning time, enhance operational efficiency, and lower space requirements for production lines with the same cycle time;

Automatic adjustment of mover positions based on workpiece size and enable fast changeovers.

| Production line cycle time | 72 PPM |

| Footprint savings | 50% |

FTS-HT Motor Air Gap Parameters

| Motor air gap (mm) | 4 | 7 | 10 | 13 | 16 | 19 | 22 |

| Thrust value (N) with 240 mm magnetic plate |

571 | 483 | 408 | 345 | 292 | 246 | 208 |

| Thrust value (N) with 480 mm magnetic plate |

1142 | 965 | 816 | 690 | 583 | 493 | 417 |

| Thrust value (N) with 720 mm magnetic plate |

1713 | 1448 | 1224 | 1035 | 739 | 739 | 625 |

| Thrust value (N) with 960 mm magnetic plate |

2284 | 1931 | 1632 | 1380 | 1166 | 986 | 833 |

| Motor air gap (mm) | 4 | 7 | 10 | 13 | 16 | 19 | 22 |

| Thrust value (N) with 240 mm magnetic plate |

571 | 483 | 408 | 345 | 292 | 246 | 208 |

| Thrust value (N) with 480 mm magnetic plate |

1142 | 965 | 816 | 690 | 583 | 493 | 417 |

| Thrust value (N) with 720 mm magnetic plate |

1713 | 1448 | 1224 | 1035 | 739 | 739 | 625 |

| Thrust value (N) with 960 mm magnetic plate |

2284 | 1931 | 1632 | 1380 | 1166 | 986 | 833 |

FTS-HT Basic Parameters

Repetitive positioning accuracy

±0.1 mm

Max. Speed

3.5 m/s

Configuration software

iFTS-Studio

Communication interfaces

EtherCAT Modbus/TCP PROFINET CC-Link CANopen POWERLINK

Max. Number of modules

255

Max. Number of movers

255

Production line expandability

Both software and hardware support modular expansion

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields