160 PPM

Assembly inspection efficiency

99.8%

Product yield(≥)

85%

OEE(≥)

Introduction

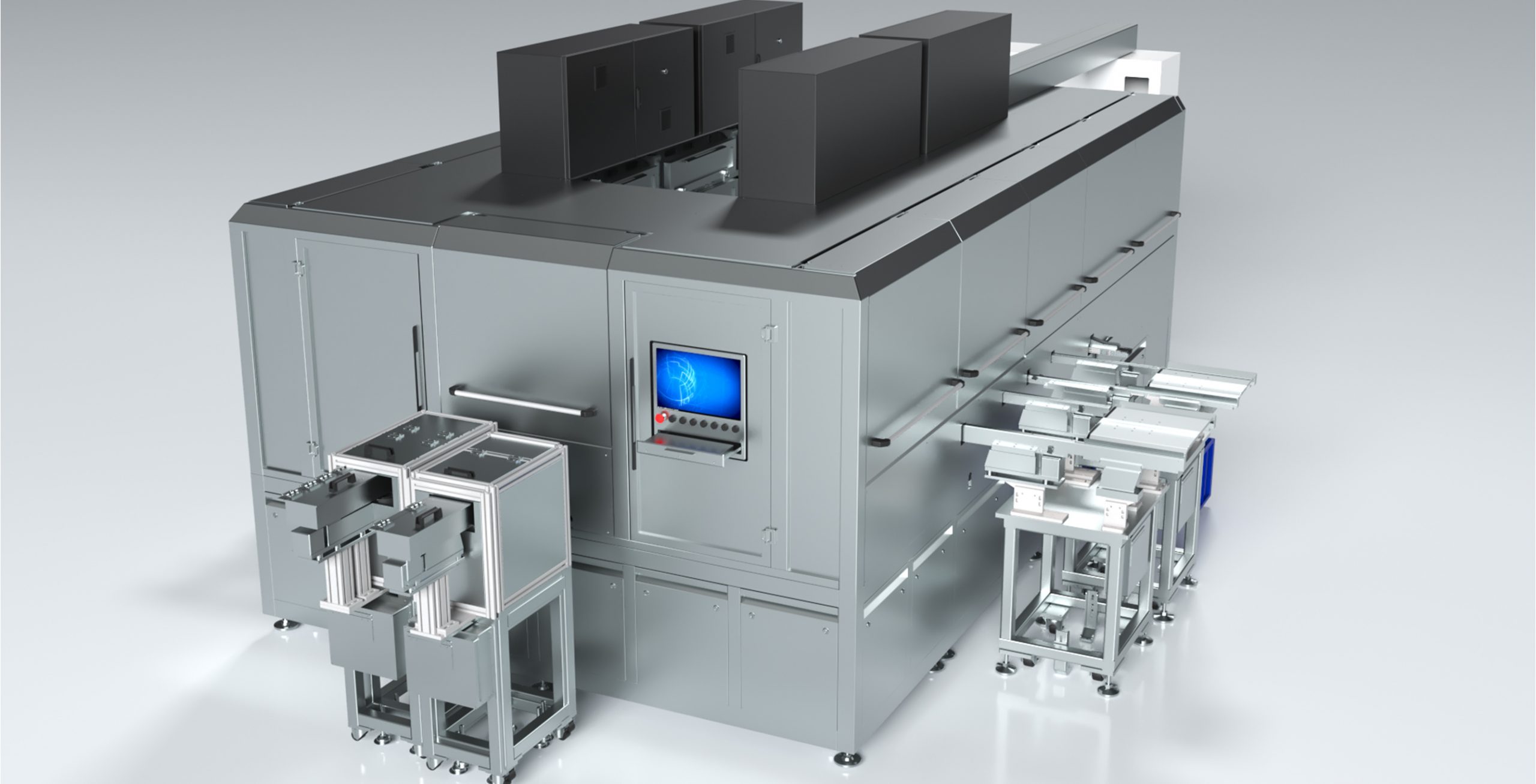

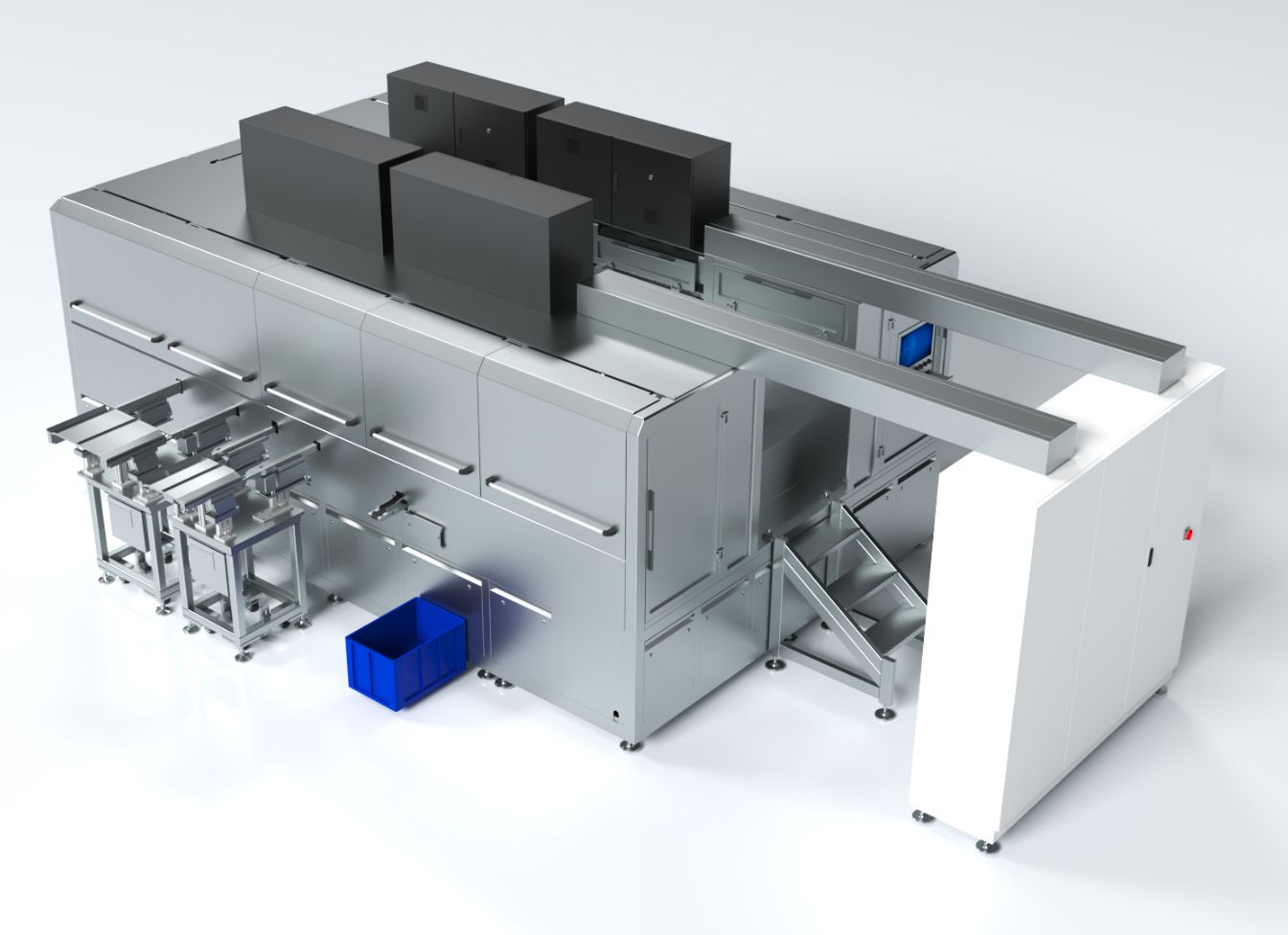

Pre-filled pen type insulin injector, with a main assembly equipment structure, including 13 types of material feeding assembly, mainly composed of automatic feeding of some vibrating discs, manual feeding of some materials, magnetic levitation carrier conveying system, cam high-speed retrieval and release system, post pressing detection system, and cutting of good and bad products.

Highlights

- Adopting a magnetic levitation flexible wire body, the wire body modules can be freely combined, and the addition or reduction of moving elements can be quickly set;

- The positioning accuracy of the linear moving element is high, and the transmission speed of the tooling is fast;

- Adopting high-speed cam mechanism for material collection and discharge;

- The tool can be set to stop positioning position through software;

- Intelligent modular control system;

- Using CCD visual inspection for key fixtures;

- Equipped with anti-static devices to eliminate static electricity generated during the assembly process;

- Accurate product positioning, smooth and stable operation, and able to meet the needs of continuous production;

- After each assembly action of the equipment is completed, an independent testing station should be designed to check whether the assembly process is proceeding normally;

- The entire line operates stably, with continuous speed, adjustable assembly speed, and the ability to automatically synchronize;

- The system has comprehensive diagnostic functions to identify and explain faults, displaying the cause of equipment shutdowns;

Parameters

Equipment Production Rate

160PCS/PPM

Product Qualification Rate

≥99.8%

Equipment OEE

≥85%

Max. Conveying Speed

4 M/S

Average Speed of Circular

Orbit Operation

2M/S

Overall size

L8500*W5500*H2100mm

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields