±0.01 mm

Repetitive positioning accuracy

5 - 40 kg

Single mover load range

847 N

Max. Thrust

5 m/s

Max. Speed

Product Highlights

- Quick mover and tooling replacement for different product types

- Modular design adapts to various production needs

- Customizable workstations with expandable motor integrated modules and movers

- Designed for long-term use with multiple product iterations and process upgrades

- Motor integration modules for both straight and curved sections, and multiple mover modules can be controlled simultaneously

- High-precision positioning for both straight and curved sections

Application cases

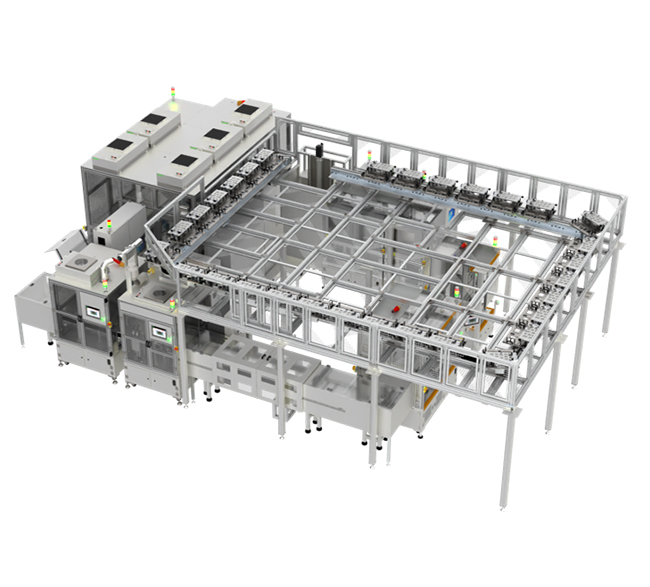

Design Focus: Assembly of prismatic battery top cover.

Features: Maglev for high-speed transfer while automating the feeding of key components;

AGV interface for future upgrades;

3D vision inspection, helium leak testing, ultrasonic welding, laser barcode engraving/welding.

Quality Assurance: Automatic electrical performance tests, removal of NG products, and stacking of only qualified items.

Advantages:

Optimized process cycle time for top cover assembly, reduced time for welding changeover and improved changeover flexibility;

Seamless integration with MES system, enhanced product quality traceability;

Single fixture use, minimized product handling and transfer, improved overall yield and line efficiency.

| Repetitive positioning accuracy | ±0.02 mm |

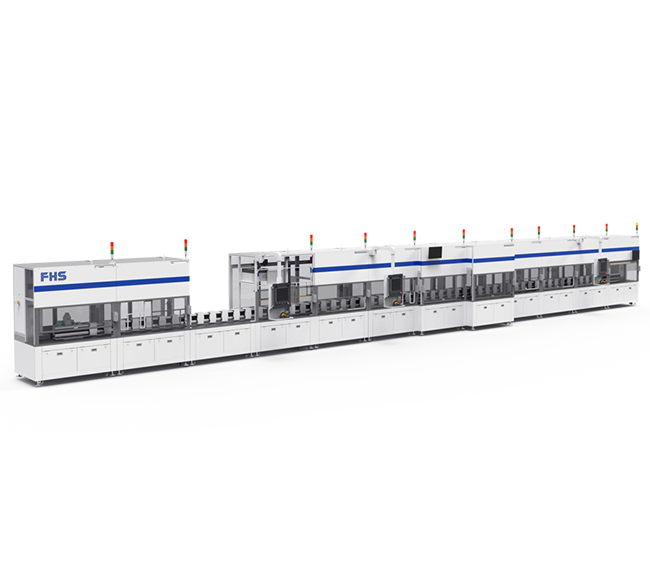

Design Focus: A high-speed, high-precision, and highly flexible production line utilizing magnetic levitation for material conveyance.

Features: Equipped with a full-ring guide rail for heavy loads and enhanced stability;

Uses a sealed high-speed servo transfer module for smooth and flexible material handling, preventing secondary contamination;

RFID technology binds with test tube information for full-process traceability.

Advantages:

No secondary positioning required, simplified equipment setup;

Faster transport speeds and equipment efficiency up to 1.5 s /4 pcs;

Flexible production, quick product changeovers within 15 minutes.

| Average running speed of the circular track | 3 m/s |

| Max. Acceleration | 3 g |

| Mover repetitive positioning accuracy | ±0.02 mm |

Design Focus: Automatic glue dispensing on automotive smart central control screens.

Features: Magnetic levitation for high-speed product transfer with automatic feeding of displays, backlight modules, and brackets;

Meets ISO Class 7 cleanliness standards.

Advantages:

Replace single track conveyor lines, shorter delivery time, lower costs, and higher transport efficiency;

Higher precision, no need for secondary positioning, each mover treated as a single axis, thereby reducing robotic configurations across several stations.

| Positioning accuracy | ± 0.03 mm |

| Cycle time | <26 s |

| Cost reduction | >10% |

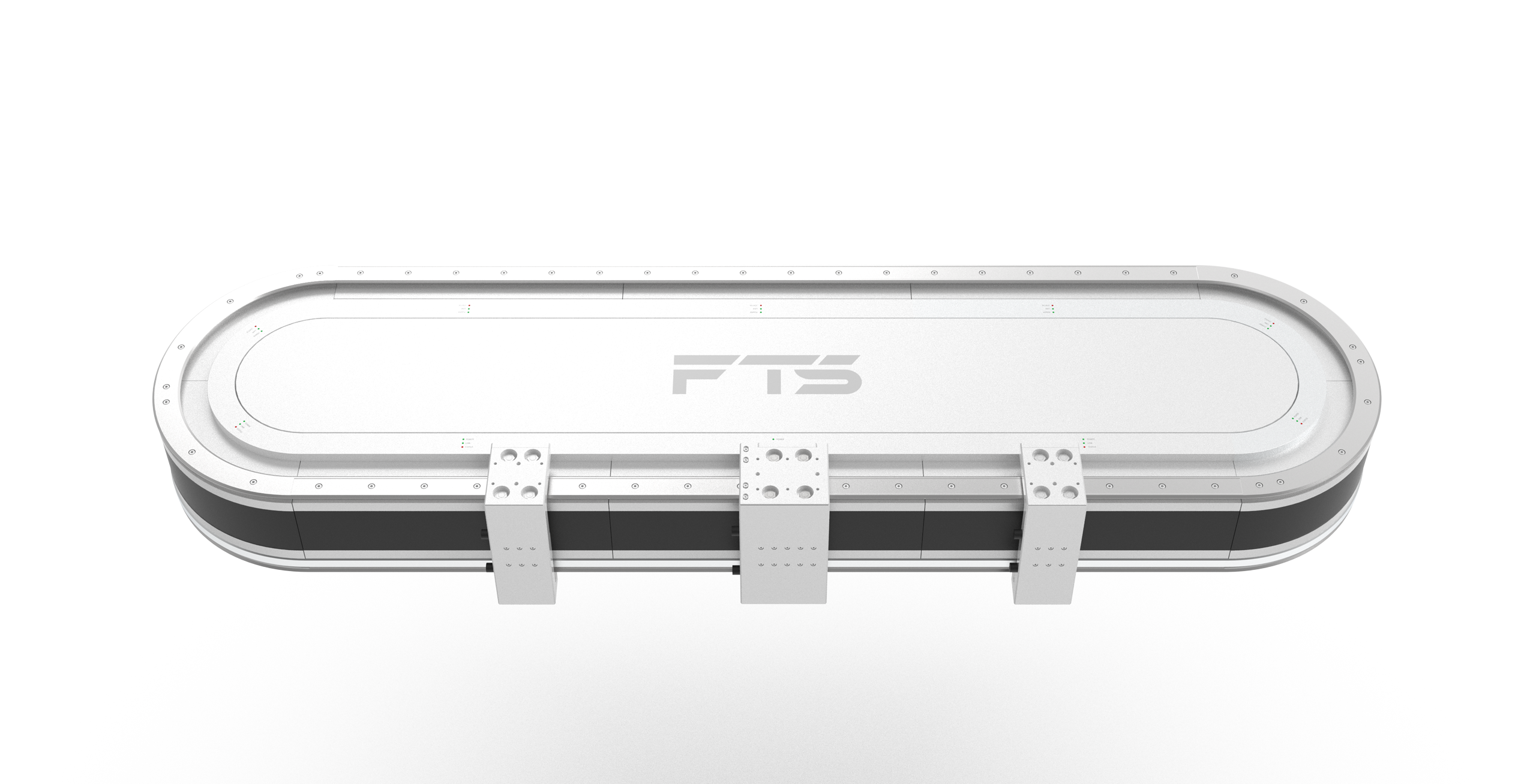

FTS-MT Motor Integrated Module Parameters

| Motor integrated module | C050 | C075 | |||

| Magnetic plate width (mm) | 80 | 120 | 160 | 120 | 160 |

| Peak thrust (N) | 290 | 435 | 580 | 635 | 847 |

| Max. Speed (m/s) | 5 | 4 | |||

| Motor integrated module | C050 | C075 | |||

| Magnetic plate width (mm) | 80 | 120 | 160 | 120 | 160 |

| Peak thrust (N) | 290 | 435 | 580 | 635 | 847 |

| Max. Speed (m/s) | 5 | 4 | |||

FTS - MT Basic Parameters

Typical load

≤40 kg

Repetitive positioning accuracy

±0.01 mm

Power supply voltage

DC 48V

Configuration software

iFTS-Studio

Communication interfaces

EtherCAT Modbus/TCP PROFINET CC-Link CANopen POWERLINK

Max. Number of modules

255

Max. Number of movers

255

Production line expandability

Both software and hardware support modular expansion

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields