±0.03 mm

Repetitive positioning accuracy

10 kg

Max. Load

580 N

Max. Thrust

5 m/s

Max. Speed

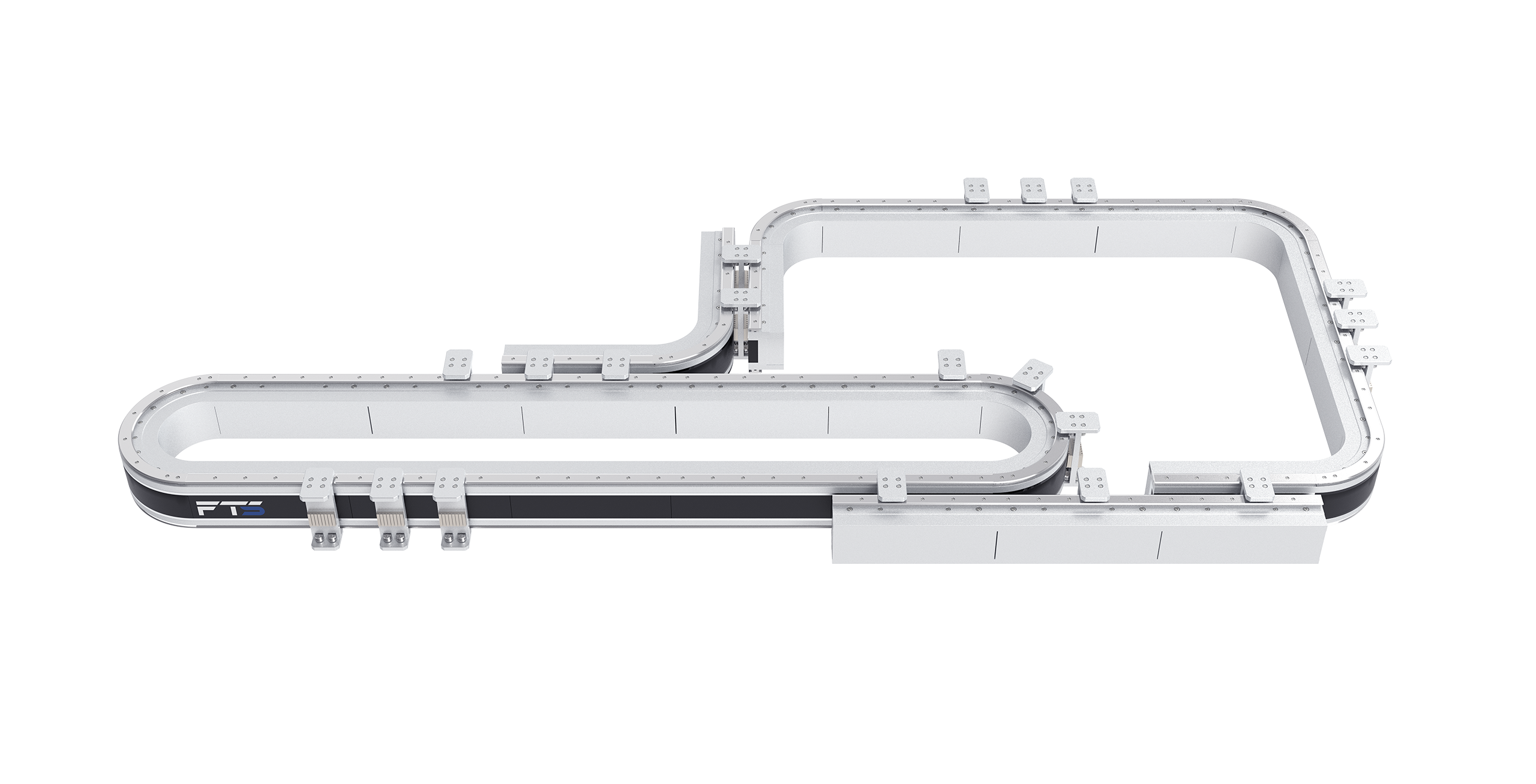

Product highlights

- Double-sided magnetic plates, support for changing track easily

- Forked reflux, flexible track switching

- Quick mover and tooling replacement for different product types

- Modular design adapts to various production needs

- Customizable workstations with expandable motor and mover modules

- Designed for long-term use with multiple product iterations and process upgrades

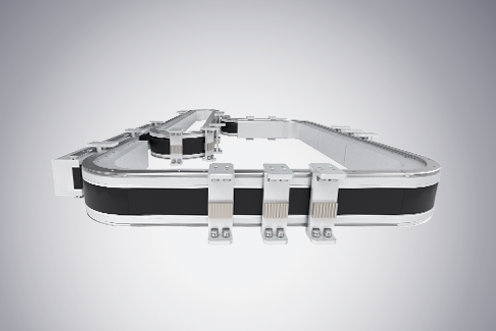

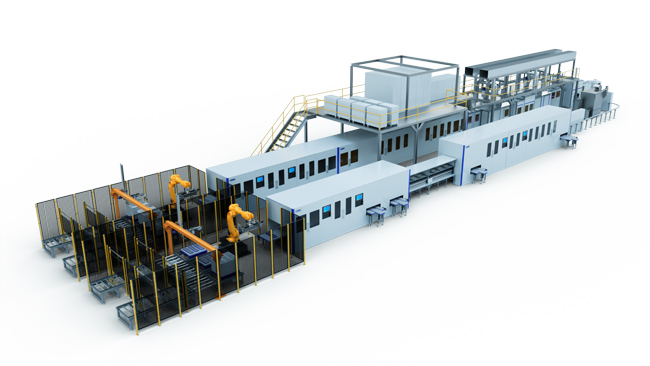

Application cases

Design Focus: Laser texturing and plasma cleaning of lithium-ion battery cells.

Features: Magnetic levitation for high-speed transfer; dual-mover clamping technique for remarkable flexibility;

Process including automatic feeding, laser cleaning, plasma cleaning, cell orientation, and automatic unloading.

Advantages:

Flexible Cell Size Adaption: rapid changeover between six different cell sizes;

Precision Operations: high repetitive positioning accuracy, no need for secondary positioning, synchronized operation with laser cleaning.

| Production line cycle time | 60 ppm |

FTS-LT Motor Integrated Module Parameters

| Motor integrated module | C050 | ||

| Magnetic plate width (mm) | 80 | 120 | 160 |

| Peak thrust (N) | 290 | 435 | 580 |

| Motor integrated module | C050 | ||

| Magnetic plate width (mm) | 80 | 120 | 160 |

| Peak thrust (N) | 290 | 435 | 580 |

FTS-LT Basic Parameters

Typical load

≤10 kg

Repetitive positioning accuracy

±0.03 mm

Max. Speed

5 m/s

Power supply voltage

DC 48V

Configuration software

iFTS-Studio

Communication interfaces

EtherCAT Modbus/TCP PROFINET CC-Link CANopen POWERLINK

Max. Number of modules

255

Max. Number of movers

255

Production line expandability

Both software and hardware support modular expansion

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields