Application

Scenarios

Diagnostic equipment, testing equipment, therapeutic equipment,

rehabilitation equipment,auxiliary equipment, medical consumables, etc.

Medical Industry Application

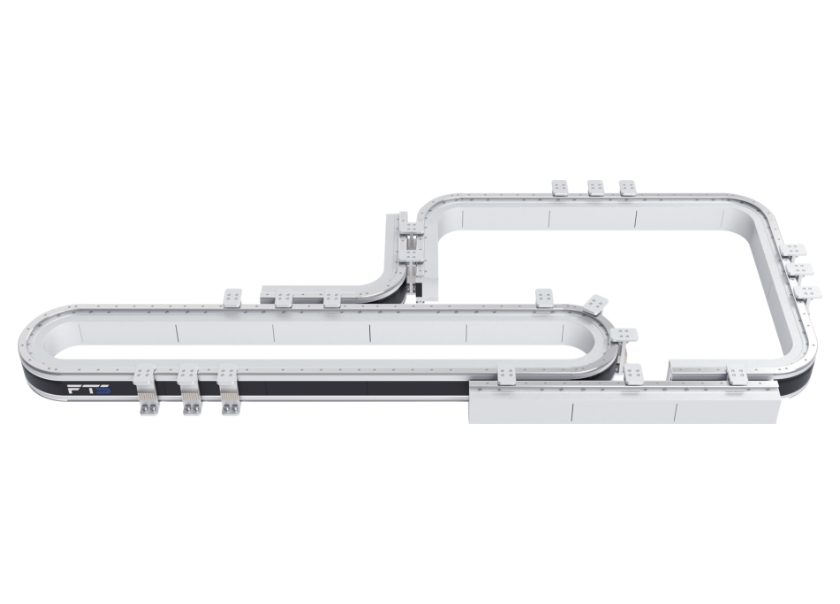

Medical devices vary widely, with particularly complex manufacturing requirements for small-sized products. These products demand exceptional assembly precision, as well as strict standards for cleanliness, noise reduction, and reliability. The FTS maglev conveyor system, with its high speed, precision, and low-friction design, is engineered to meet the stringent demands of medical production environments.

Product Highlights

- With repetitive positioning accuracy of ±0.01 mm, the FTS system enhances assembly precision while reducing equipment complexity.

- Its roller-based design minimizes friction, resulting in lower noise levels. Additionally, it is ISO 6-certified for cleanliness, meeting the strict standards of the medical industry.

Application Cases

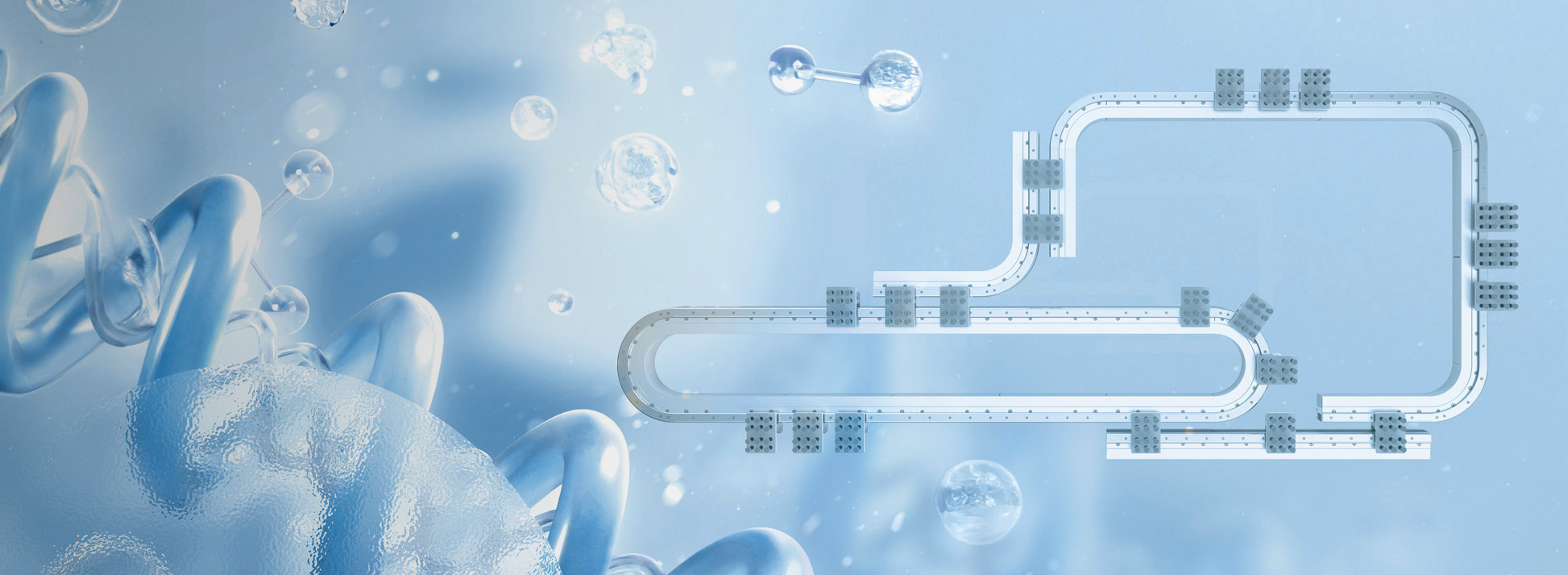

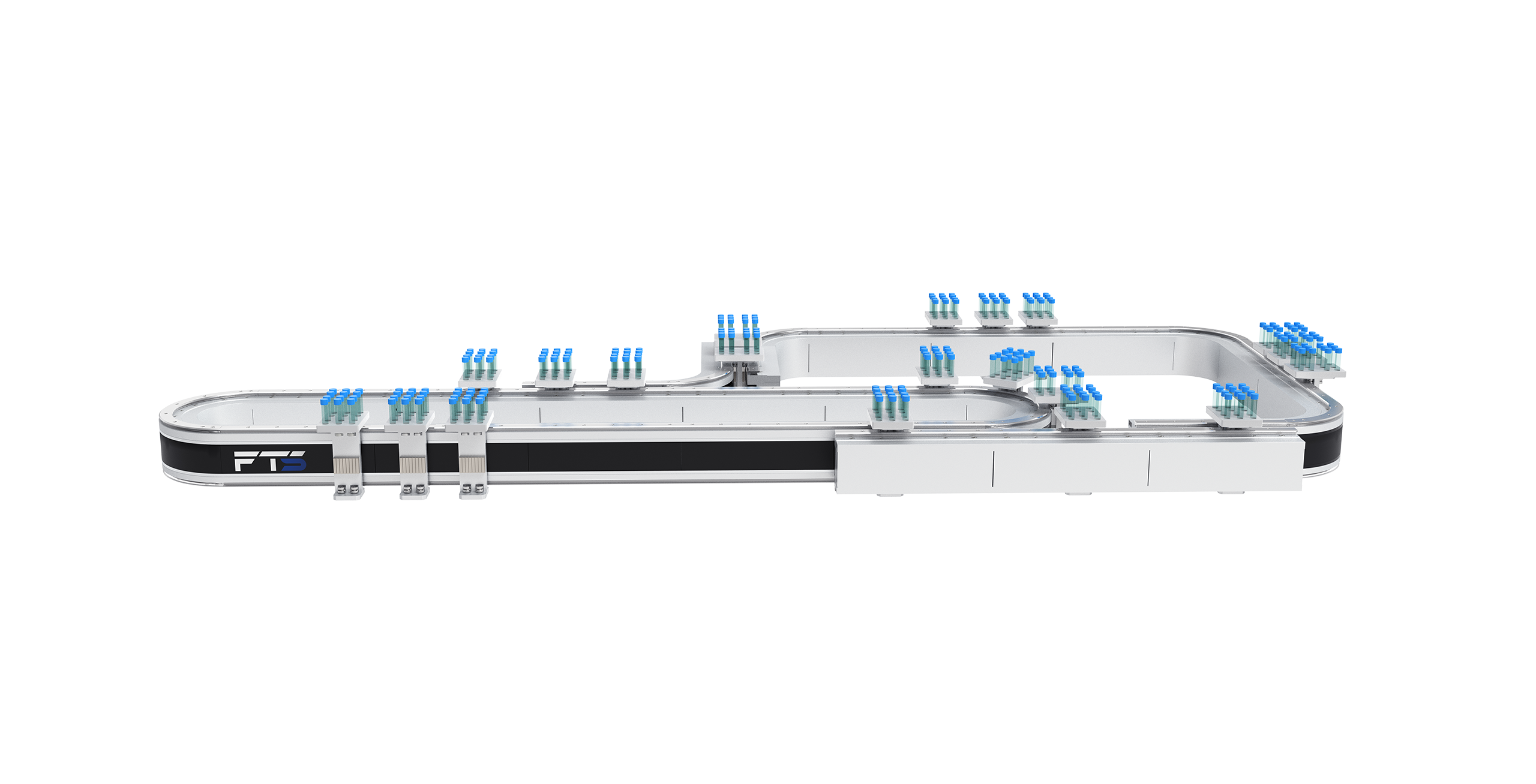

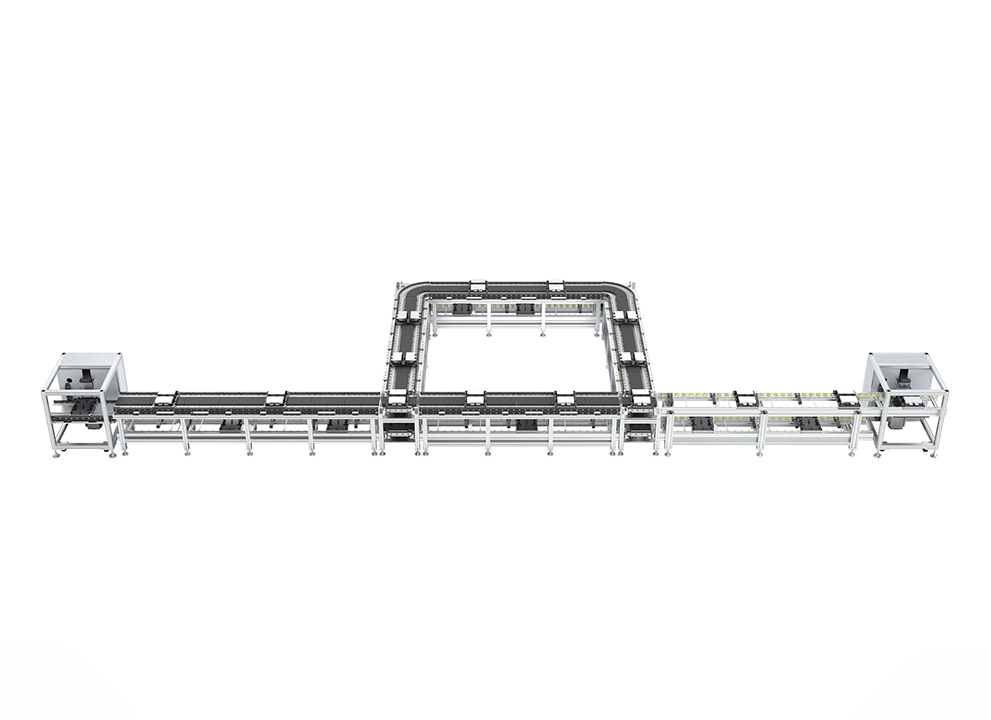

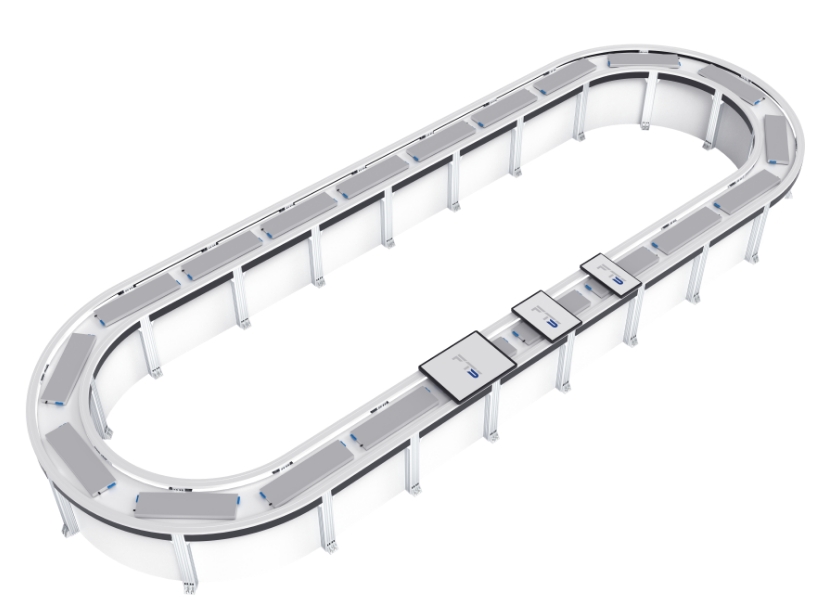

Design Focus: A high-speed, high-precision, and highly flexible production line utilizing magnetic levitation for material conveyance.

Features: Equipped with a full-ring guide rail for heavy loads and enhanced stability;

Uses a sealed high-speed servo transfer module for smooth and flexible material handling, preventing secondary contamination;

RFID technology binds with test tube information for full-process traceability.

Advantages:

No secondary positioning required, simplified equipment setup;

Faster transport speeds and equipment efficiency up to 1.5 s /4 pcs;

Flexible production, quick product changeovers within 15 minutes.

| Average running speed of the circular track | 3 m/s |

| Max. Acceleration | 3 g |

| Mover repetitive positioning accuracy | ±0.02 mm |

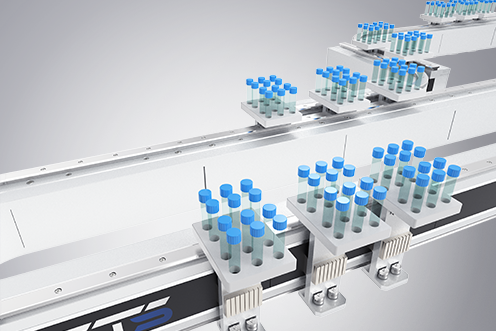

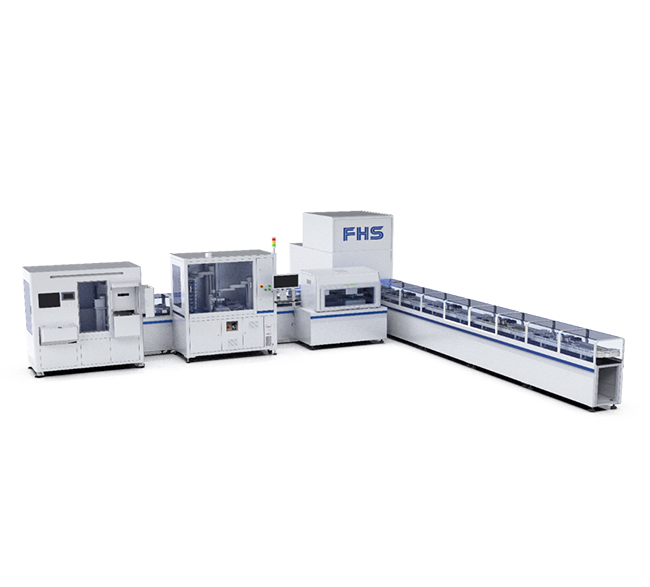

Design Focus: Automation of fluorescence PCR processes in the medical industry.

Processes Automated: Information processing, centrifugation, cap removal, sample storage, etc.

Key Modules: Tipping sample loading module, high-surge tray loading module, low-temperature centrifuge module, cap-removal and sorting block, emergency priority loading module, off-line sorting and sample output module, on-line refrigerator (5000-tube capacity) module, on-line refrigerator (3000-tube capacity) module, capping module, on-line sampling connections for biochemical analyzers (FX8 mode), on-line sampling connections for chemiluminescence analyzers (A2000Plus mode), and a secondary cap removal module, etc.

Advantages:

Circular track system, Large load capacity, Enhanced stability;

Expandable Layout;

RFID technology, tube information binding, full-process traceability of information.

Recommended Products

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields