Application Scenarios

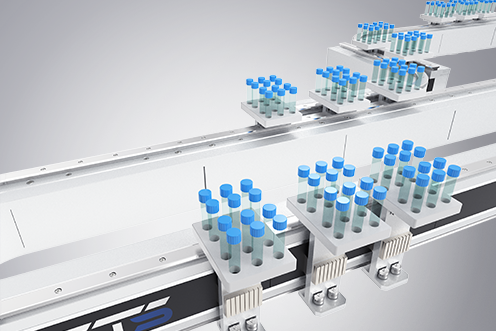

The FTS maglev transport lines reach a maximum speed of 5 m/s, supports loads up to 5000 kg, and achieves repetitive positioning accuracy of ±0.005 mm. It is widely used in industries such as lithium-ion batteries, automotive, medical, 3C, and semiconductors, providing intelligent, flexible, and high-value solutions for smart manufacturing.

Application Scenarios

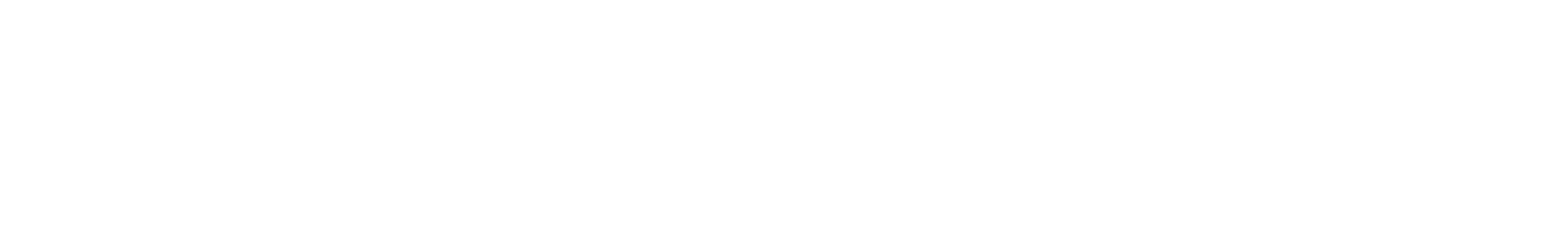

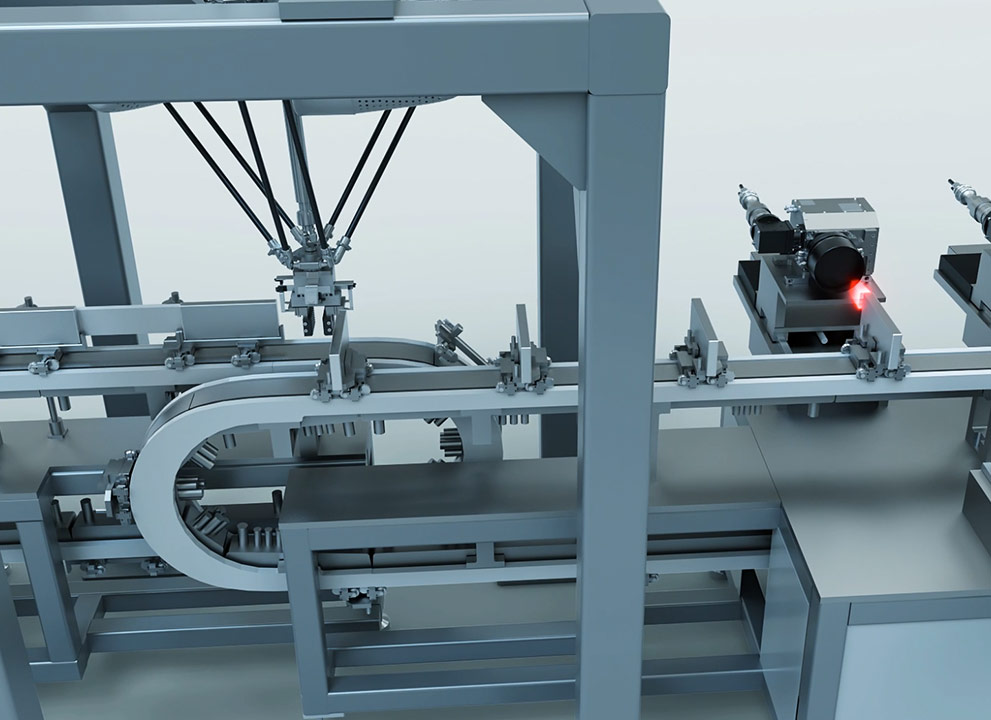

- The FTS features a modular architecture supporting multiple topologies, including straight paths, loops, and diverging.

- Its flexible assembly allows seamless adaptation to different product types and evolving production processes.

- With built-in simulation and multi-terminal debugging, it enables production cycle pre-testing to accelerate delivery times.

- Each mover operates independently, offering precise control at any position, high-accuracy positioning, and intelligent scheduling.

- The system dynamically bypasses faulty workstations and allows movers to be added or removed without stopping production, significantly boosting efficiency.

By overcoming the limitations of traditional conveyors, it introduces a smarter, more flexible, and cost-effective solution.

Application Cases

Get a solution now

We will tailor an exclusive project plan for you by assessing your business needs, reviewing the current project status, and analyzing your competitors in the industry.

"*" indicates required fields