Market Activities

2025/09/27

CIIF Closes with Great Success! FHS Group’s FTS Solution Redefines Smart Conveyance with an “Interactive Experience”

27

2025/09/

On September 27, 2025, the 25th China International Industry Fair (CIIF) came to a triumphant close at the National Exhibition and Convention Center in Shanghai. FHS Group (Hall 6.1, Booth C112) stole the spotlight with its futuristic and fully immersive booth design. Through four live dynamic demonstrations and an innovative “mystery box” interactive experience, visitors were able to experience the unique appeal of magnetic levitation conveying technology up close.

Four Core Demonstrations Ignite Crowd Enthusiasm

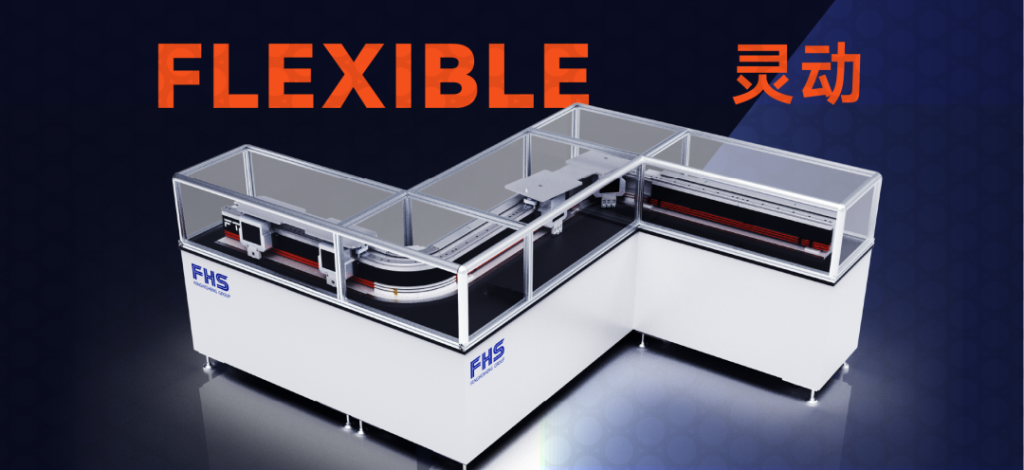

①Modular and Highly Adaptable FTS Pallet Logistics Line

Equipped with standard rotating, diverging, merging, and straight-track modules, this demonstration perfectly replicated mixed-model production scenarios, resonating strongly with industry professionals and customers alike.

②Wireless Power Supply plus Line-Scan Integration, Revolutionizing Inspection Efficiency

Wireless power supply: Breaks free from the friction and wear limitations of traditional sliding contact lines, delivering contactless power to movers’ onboard vacuum pumps and dramatically reducing maintenance.

Synchronized line-scan triggering: High-speed digital output responds instantly to mover speed variations, enabling the line-scan camera to capture flawless images even with speed fluctuations of 0.1-second, achieving imaging accuracy of ±10 μm and ensuring outstanding yield rates.

③S-Curve Track plus Dual-Mover Collaboration, a Breakthrough in Heavy-Duty Applications

The dual-mover synchronized load-bearing design pushes beyond conventional magnetic levitation payload limits, enabling smooth operation on both inner and outer curves-making it ideal for demanding automotive welding and painting lines.

④Multi-Axis Synchronous Control System, an Intelligent Cross-Device Collaboration

Powered by the iFCS magnetic levitation control platform, the system supports interpolated motion of multiple movers and seamless integration with robotic arms and servo axes, significantly simplifying the structure of external workstations.

Interactive Highlight: FTS Mystery Box Became the Hottest Experience on Site

A specially designed “FTS Mystery Box” raffle turned the booth into a crowd magnet. Visitors used the iFTS-Studio intelligent configuration software to select a number, then watched their personalized mystery box be delivered precisely via magnetic levitation conveying – an intuitive and exciting showcase of FTS intelligence in action. The activity attracted over 500 participants throughout the exhibition, making it one of the most popular interactive attractions in the hall.

Looking ahead, FHS Group’s Flexible Transport System (FTS) will continue driving intelligent upgrades across new energy, semiconductor, automotive manufacturing, and other key industries, harnessing the power of magnetic levitation to reshape the future of high-efficiency production.

Based in East China,

Reaching Out Worldwide

FHS Group is based in East China, with a global layout. FHS Group has after-sales service outlets and partners in many countries and regions around the world, and has set up subsidiaries in the U.S.A., Germany and Hungary, and maintains after-sales team and partners in France, Spain, the Czech Republic, Romania, Mexico, Poland, Hungary, South Korea, India and other countries.

Leading in Intelligent Manufacturing

and Multi-Industry Development

Founded in 2010 and headquartered in Kunshan, Jiangsu Province, FHS Group is a global one-stop smart manufacturing solution provider. There are more than 2,000 employees, of which R&D team accounts for more than 60%. The business scope covers new energy, auto parts and life sciences and other intelligent manufacturing fields, providing intelligent, digital, flexible intelligent manufacturing production solutions and core equipment data services.

Continuous Management Optimization

for High-Quality Industry Development

FHS Group is committed to promoting digital, modular and lean management. We have a strong grasp of a number of core technologies, including control perception, laser processing technology and digital information technology. This allows us to consolidate our absolute competitive advantage as an enterprise. By continuously enhancing systematic management and optimizing our supply chain, project management, and talent development systems, we support rapid business growth. We are dedicated to breaking new ground in cutting-edge technologies and exploring innovative solutions in intelligent manufacturing, driving high-quality development across the industry.

Public Relations Officer

Miss Zeng