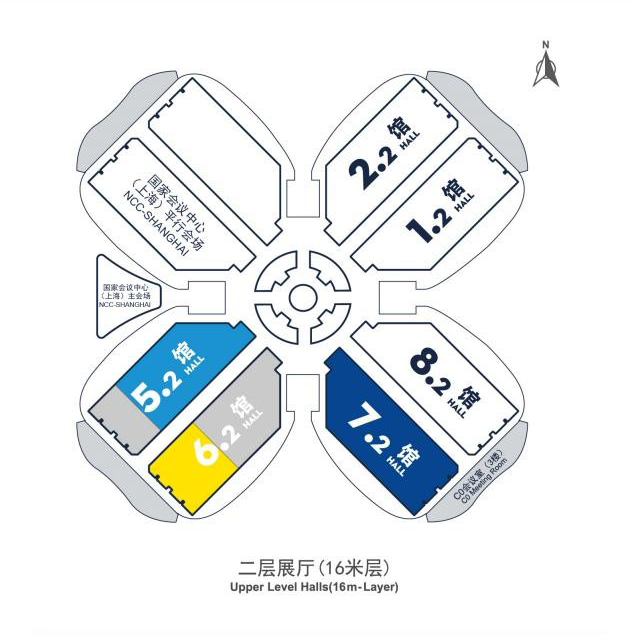

From September 24th to 28th, the 24th China International Industry Fair (CIIF 2024) was held at the National Exhibition and Convention Center (Shanghai). The event featured over 2,600 exhibitors from 28 countries and regions, covering 280,000 square meters, and showcased the latest industrial technologies and innovations.

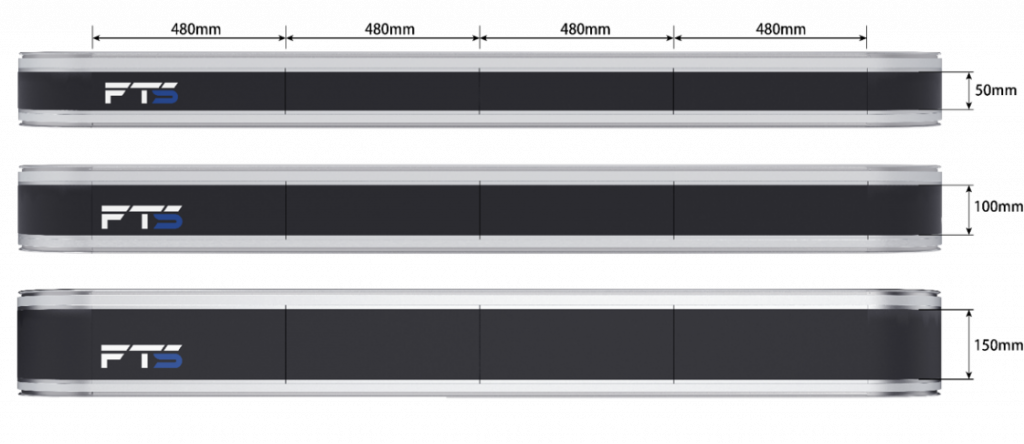

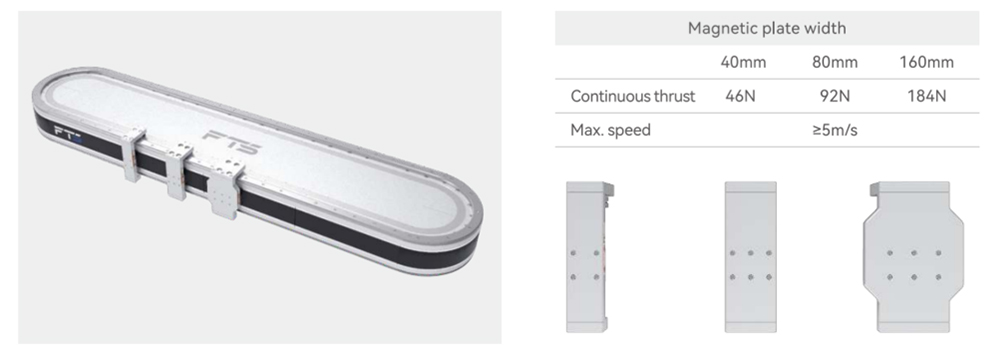

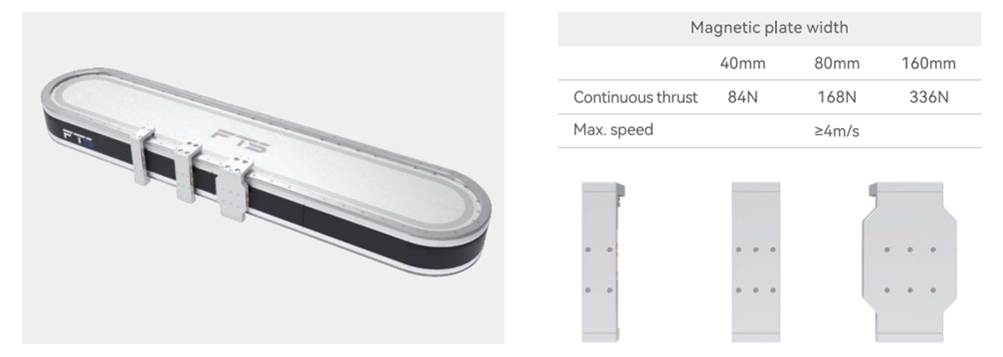

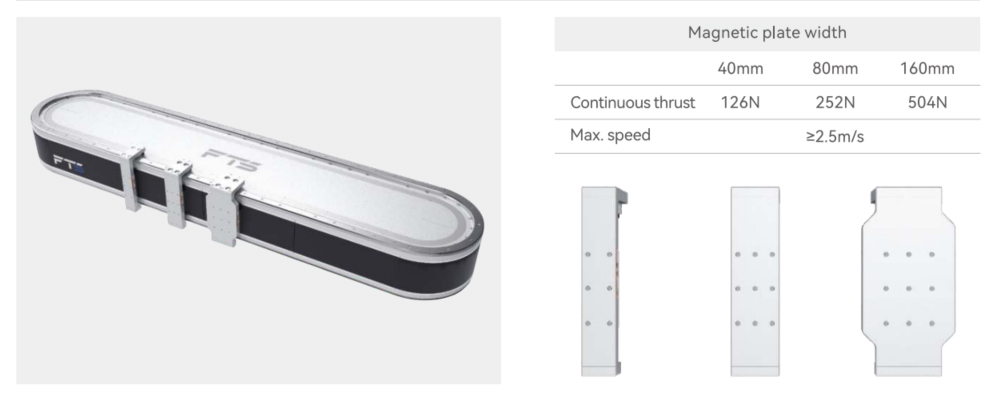

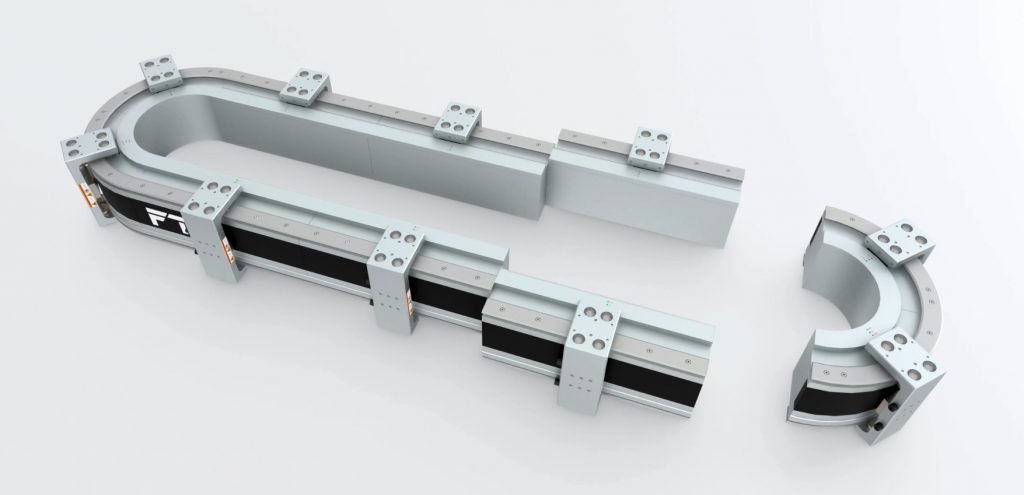

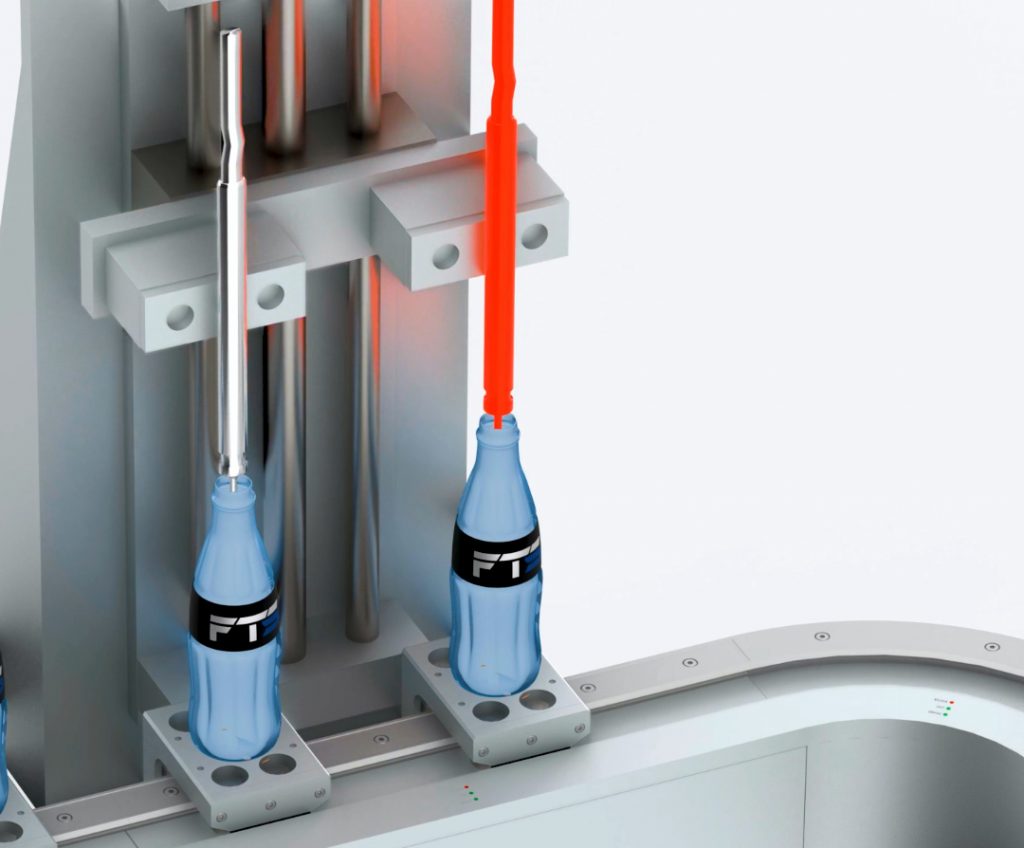

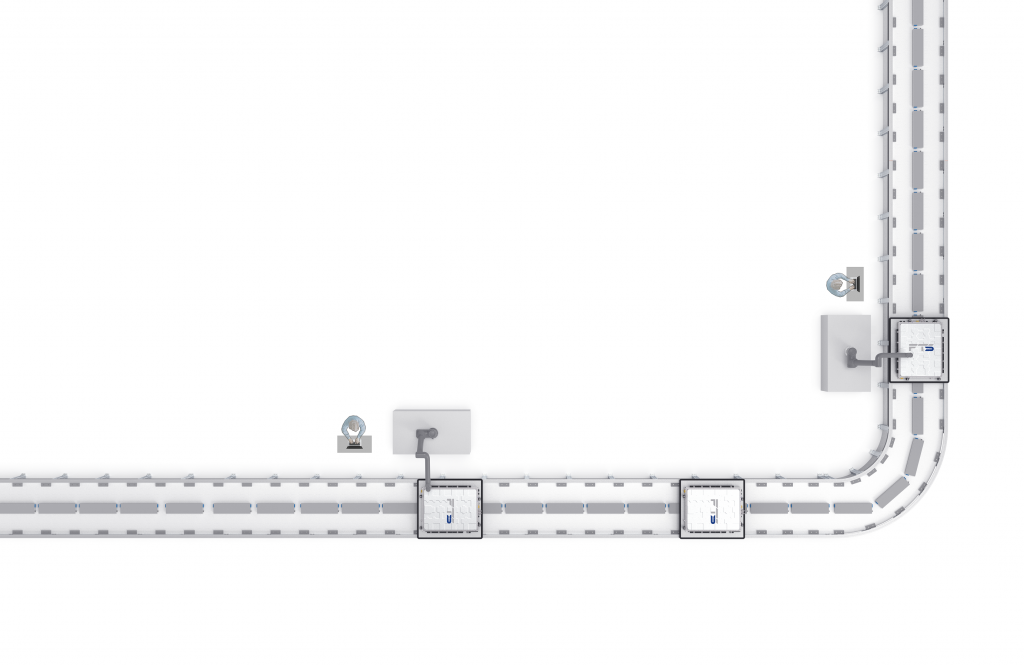

At this year’s CIIF, FHS Group presented its intelligent magnetic levitation conveyor series, FHS Flexible Transport System (FTS). This production line includes the FTS High Thrust Series (FTS-HT), FTS Medium Thrust Series (FTS-MT), and FTS Light Thrust Diverge Series (FTS-LT). These advanced products drew significant attention, highlighting FHS Group’s technological expertise.

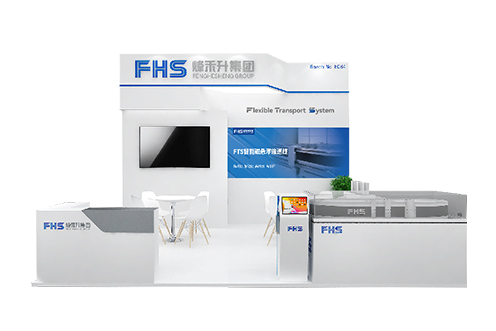

Focusing on industrial intelligent transport systems, FHS Group’s booth stood out among the exhibitors. The live demonstration of the FTS-MT, with its seamless operation and superior performance, drew a lot of industry professionals and clients for detailed discussions.

To give the industry a better understanding of its magnetic levitation technology, FHS Group also held an “FTS Maglev Product Launch Event” at the CIIF conference center. The event was aimed at industry experts, clients, and media. It introduced the latest technology along with the applications and benefits of the intelligent magnetic levitation system, receiving great interest and positive feedback from the audience.

As a leader in smart, digital, and flexible manufacturing, FHS Group has extensive experience and expertise in sectors like new energy, medical devices, and automotive automation. The launch of the “Flexible Transport System” (FTS) showcases our dedication to innovation and delivering practical solutions.

These technological breakthroughs are the result of deep insights and analysis of traditional industrial transport systems. In future, FHS Group will continue to lead in the intelligent transport field, supporting industry clients in achieving high-quality growth and driving a new era of intelligent transportation.

Based in East China,

Reaching Out Worldwide

FHS Group is based in East China, with a global layout. FHS Group has after-sales service outlets and partners in many countries and regions around the world, and has set up subsidiaries in the U.S.A., Germany and Hungary, and maintains after-sales team and partners in France, Spain, the Czech Republic, Romania, Mexico, Poland, Hungary, South Korea, India and other countries.

Leading in Intelligent Manufacturing

and Multi-Industry Development

Founded in 2010 and headquartered in Kunshan, Jiangsu Province, FHS Group is a global one-stop smart manufacturing solution provider. There are more than 2,000 employees, of which R&D team accounts for more than 60%. The business scope covers new energy, auto parts and life sciences and other intelligent manufacturing fields, providing intelligent, digital, flexible intelligent manufacturing production solutions and core equipment data services.

Continuous Management Optimization

for High-Quality Industry Development

FHS Group is committed to promoting digital, modular and lean management. We have a strong grasp of a number of core technologies, including control perception, laser processing technology and digital information technology. This allows us to consolidate our absolute competitive advantage as an enterprise. By continuously enhancing systematic management and optimizing our supply chain, project management, and talent development systems, we support rapid business growth. We are dedicated to breaking new ground in cutting-edge technologies and exploring innovative solutions in intelligent manufacturing, driving high-quality development across the industry.