In today’s rapidly evolving new energy market, the lithium battery, as one of the key drivers, has its production efficiency and technological advancements playing an important role in overall market competition. In this article, we’ll share a successfully implemented case using the FTS Intelligent Maglev Conveyor System in prismatic cell module assembly lines within the lithium battery industry. It demonstrates how smart technology is tackling traditional production challenges of efficiency and flexibility.

Customer Background and Production Line Application Requirements

The client in this case specializes in the lithium battery sector, their prismatic cell module assembly line deals with the process from raw materials into finished battery products. The production process is intricate, involving automatic material loading and transfer with AGVs, robotic vision-guided unpacking, sorting, and scanning of batteries and cooling plates, cell OCV testing, adhesive application and inspection, grouping of cells into beams, and stack formation into battery blocks. These processes pose high challenges to the conveyor system on precision, efficiency, and flexibility.

FTS Intelligent Maglev Conveyor: A Game-Changing Solution

To overcome these challenges, the customer introduced the FTS Intelligent Maglev Transport System, bringing revolutionary improvements to the prismatic cell module assembly line. This system has particularly excelled in the high-speed transfer loop for cooling plates and has demonstrated its exceptional performance as follows:

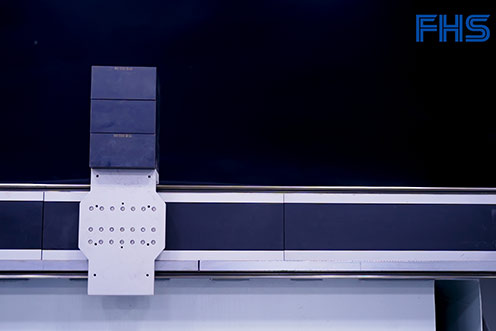

Efficient Transfer Loop: FTS’s magnetic levitation technology enables smooth, high-speed transport of cooling plates, significantly boosting overall production efficiency.

High Flexibility and Compatibility: The FTS system is customized and adapted seamlessly to different sizes of cooling plates, satisfying diverse production requirements of different battery modules, and reducing changeover time and costs.

Intelligent Control: The FTS system supports both group and bidirectional movement, and thus enhances transfer efficiency. In cases of product defects (NG), the mover can quickly retract, keeping the continuity and flexibility of the production process.

Adjustable Spacing, No Fixtures Needed: The conveyor system’s spacing can be limitlessly adjusted without the additional fixtures required, simplifying operations and improving production flexibility.

Quick Changeover: When switching cooling plates, the system only requires parameter change, eliminating the need for physical components change. This significantly reduces changeover time and improves the line’s ability to quickly adapt to market demands.

The FTS Intelligent Maglev Conveyor System helped the customer overcome challenges of traditional conveyor lines. It also delivered significant improvements in production efficiency and cost savings through its flexibility, smart control, and superior performance. This successful practice underscores the vast potential of FTS maglev technology in automatic lithium battery production lines, offering valuable references for other industries. As technology continues to evolve, FTS will continue to demonstrate its unique value across various fields, driving manufacturing toward greater intelligence and efficiency.

Based in East China,

Reaching Out Worldwide

FHS Group is based in East China, with a global layout. FHS Group has after-sales service outlets and partners in many countries and regions around the world, and has set up subsidiaries in the U.S.A., Germany and Hungary, and maintains after-sales team and partners in France, Spain, the Czech Republic, Romania, Mexico, Poland, Hungary, South Korea, India and other countries.

Leading in Intelligent Manufacturing

and Multi-Industry Development

Founded in 2010 and headquartered in Kunshan, Jiangsu Province, FHS Group is a global one-stop smart manufacturing solution provider. There are more than 2,000 employees, of which R&D team accounts for more than 60%. The business scope covers new energy, auto parts and life sciences and other intelligent manufacturing fields, providing intelligent, digital, flexible intelligent manufacturing production solutions and core equipment data services.

Continuous Management Optimization

for High-Quality Industry Development

FHS Group is committed to promoting digital, modular and lean management. We have a strong grasp of a number of core technologies, including control perception, laser processing technology and digital information technology. This allows us to consolidate our absolute competitive advantage as an enterprise. By continuously enhancing systematic management and optimizing our supply chain, project management, and talent development systems, we support rapid business growth. We are dedicated to breaking new ground in cutting-edge technologies and exploring innovative solutions in intelligent manufacturing, driving high-quality development across the industry.