Company News

2025/11/21

FHS Group Wins “Annual Value Award” at GGII Lithium Conference, Highlighting Success of Global Strategy

21

2025/11/

From November 18 to 20, 2025 Gaogong Lithium Battery Anniversary Conference & GG Gold Globe Awards, hosted by GGLB and GGII, took place in Shenzhen, China. FHS Group attended as a prominent representative in the intelligent manufacturing sector.

Themed “Reflecting on 15 Dynamic Years, Envisioning a New Journey,” this year’s conference brought together over 1,000 companies from the lithium battery industry chain and over 1,500 senior executives. Across the three-day agenda, 12 specialized forums focused on technological innovation and future strategies, addressing the challenges and opportunities amid industry cycle shifts.

FTS: Redefining High-Efficiency Transport for Lithium Battery Manufacturing

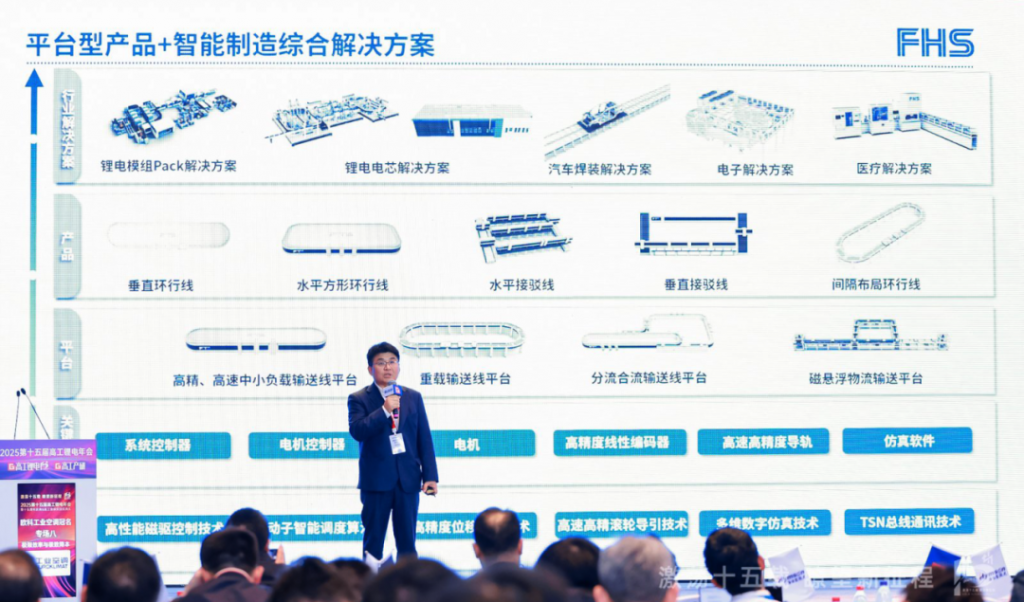

As vehicle electrification extends to every corner of mobility and the energy transition accelerates, extreme efficiency has emerged as the core driver of industrial upgrading. Drawing on more than a decade of expertise in new energy, automotive, and medical automation, FHS Group has developed its proprietary FTS intelligent magnetic levitation transport system. This breakthrough technology tackles key pain points in lithium battery production—high cycle times and complex multi-process loops—delivering powerful efficiency gains to global manufacturers.

On November 19, 2025, Dr. Huang Fuchang, Director of FHS Group’s Maglev Product Line, delivered a keynote titled “Redefining High-Efficiency Transport for Lithium Battery Manufacturing” at the “Extreme Efficiency & Cost Reduction” forum. He explained how FTS maglev technology transforms production in four critical ways:

- Speed and throughput leap: Maximum speed reaches 5 m/s, 5 or 6 times faster than conventional conveyor lines (0.8 m/s), with independent control of each mover for fully flexible cycle-time allocation.

- Ultimate cost reduction and energy savings: Less friction operation extends maintenance intervals to 6 to 24 months, significantly reducing downtime and replacement costs. Additionally, movers only consume power when activated at coil positions, resulting in notable energy savings.

- Cleanliness and Safety Assurance: The operation generates less particles, making it perfectly suited for the dust-sensitive production environments in the lithium battery industry. It also avoids cell damage caused by friction and vibration inherent in traditional conveyor systems.

- High Precision and Flexible Adaptation: Positioning accuracy reaches below 10 micrometers. The technology supports modular assembly and rapid commissioning, allows for adaptation to different cell sizes through parameter adjustments, and enables complex processes like flying welding through synchronization with external workstations, saving up to 50% of factory space.

FTS (Flexible Transport System) portfolio now includes four series:

- Light-Thrust (with electromagnetic road switching)

- Medium-Thrust (up to 40 kg payload, 5 m/s, 10 μm precision)

- Heavy-Thrust (up to 5 tons, tailored for complete assembly plants)

- Logistics (500 kg payload, 2 m/s, ideal replacement for traditional conveyor lines)

The technology is already deployed across the full lithium battery production flow, including square-cell cap assembly lines, cell UV coating lines, and module stacking lines.

Crowned with the 2025 GGII “Annual Value Award”

On the evening of November 20, the 2025 GG Gold Globe Awards—widely regarded as the “Oscars of the lithium battery industry”—announced the winners. FHS Group stood out among fierce competition for its outstanding R&D commercialization, marked global expansion, and sustained high growth, clinching the prestigious “Annual Value Award”.

In recent years, FHS Group has steadfastly pursued its dual engine growth strategy while deeply integrating the DSTE management framework and BLM (Business Leading Model). These efforts have accelerated overseas penetration, with dozens of large-scale intelligent production lines successfully delivered in over 10 countries, including the United States, Germany, and France. The FTS maglev transport system, with its high precision and flexibility, has become a benchmark in new energy, 3C, automotive, and medical sectors, steadily increasing market share.

This award not only recognizes FHS Group’s impressive business performance but also serves as authoritative validation of its global strategy.

Looking ahead, FHS Group will continue to advance its strategic triangle of “Technology Breakthrough, Global Ecosystem Expansion, and Green Intelligent Manufacturing.” Leveraging core innovations like the FTS maglev system, an expanding localized service network worldwide, and full-lifecycle management capabilities, the company is committed to leading the transformation of new-energy intelligent equipment and powering the global shift toward smarter, lower-carbon manufacturing.

Based in East China,

Reaching Out Worldwide

FHS Group is based in East China, with a global layout. FHS Group has after-sales service outlets and partners in many countries and regions around the world, and has set up subsidiaries in the U.S.A., Germany and Hungary, and maintains after-sales team and partners in France, Spain, the Czech Republic, Romania, Mexico, Poland, Hungary, South Korea, India and other countries.

Leading in Intelligent Manufacturing

and Multi-Industry Development

Founded in 2010 and headquartered in Kunshan, Jiangsu Province, FHS Group is a global one-stop smart manufacturing solution provider. There are more than 2,000 employees, of which R&D team accounts for more than 60%. The business scope covers new energy, auto parts and life sciences and other intelligent manufacturing fields, providing intelligent, digital, flexible intelligent manufacturing production solutions and core equipment data services.

Continuous Management Optimization

for High-Quality Industry Development

FHS Group is committed to promoting digital, modular and lean management. We have a strong grasp of a number of core technologies, including control perception, laser processing technology and digital information technology. This allows us to consolidate our absolute competitive advantage as an enterprise. By continuously enhancing systematic management and optimizing our supply chain, project management, and talent development systems, we support rapid business growth. We are dedicated to breaking new ground in cutting-edge technologies and exploring innovative solutions in intelligent manufacturing, driving high-quality development across the industry.

Public Relations Officer

Miss Zeng